Add new CNC capability to your CENTROID equipped CNC machine tool.

Quickly create part programs with your Windows desktop PC or Laptop.

"Intercon" is CENTROID's popular conversational part programming software. With INTERCON you can create part programs by simply entering the dimensions from your print and instantly see graphics of your work as you go. Fast and easy no CAD/CAM or G-code experince needed. Preprogrammed fill in the blank screen guide you through the programming process. Simple to make changes and see the effect immediately. The Offline version allows you to be in the comfort of your office programming the next part while the machine is running a job. click here for more information...

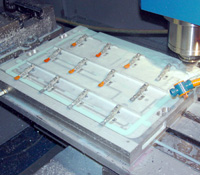

2D and 3D Digitizing software

Copy and Cut 2D and 3D shapes. Centroid's affordable, effective Digitizing is the simplest CNC Digitizing on the market. Just record and play back. Do you have a 2D contour such as a CAM or a 3D part like a mold or plug? But no print? Let our Digitizing feature copy the part for you. Digitizing turns your milling machine into a copy machine. Centroid has overcome the cumbersome problems associated with Digitizing on other controls. With our Digitizing feature you will be able to copy and reproduce an existing shape with little or no programming! No CAD/CAM necessary, but you can export the Digitzing information to a CAD/CAM system for further modification. It's very popular for repairing cylinder head combustion chamber damage, copying cams, creating molds and plugs from existing objects and many other uses.

Probing is used to quickly setup/find zero points on a vise, fixture or part. Accurately sets zero points, finds edges, center locations of bosses or bores, slots and webs. Eliminates the need for a centerfinder or an edgefinder. You'll never have to spend 30 minutes using a center finder to locate the center of a bore again. The probe will find and set the center of a bore in just seconds. In addition the probe can be used to verify part dimensions.

Probing includes DP4 Probe and probing software with CSR.

Coordinate System Rotation is often a powerful feature when combined with Probing. With CSR, you'll never have to indicate in your vise or fixture again, just bolt it to the table and the probe finds the edge automatically and rotates the machine coordinate system to match the position of your vise/fixture in seconds. If you are constantly breaking down and setting up new fixtures you need this option. It will quickly pay for itself many times over.

With a Centroid you can make all kinds of threads.You can use Tapping, Rigid Tapping and Threadmilling - depending on your part - for the best result! Centroid's advanced rigid tapping is simple to program and will both tap a hole in the regular way AND will also can peck tap a thread. Peck tapping taps a hole much in the same way as you would by hand. It allows you to tap a much larger hole than the HP of your machine would normally allow!

Our Extended WCS (additional 12 wcs) option gives you 18 total individual

part zero positions. Each zero point can be adjusted at any time.

The control remembers the positions so there is never a need to

reset, even in the event of a power loss. Many uses, this feature

allows you to have multiple zero locations in memory. Each vise

or fixture can have its own zero point. With WCS you can interupt

a job run, set another vise up on the table with new zero, machine

that job and return to the original job all without distrubing your

original zero point. this is just one example of a time saving use

of WCS.

G54,55,56,57,58,59 Free with control purchase or

software upgrade.

Set up your tools in a quarter of the time it would normally take! If you often machine short-run parts and are always setting up and tearing down for a new job, the TT-1 Auto tool set will save you tons of time while more accurately setting your tool height offsets. With the TT-1 you can create more parts per hour since the tool setup is so much faster. You'll even save time when you have to replace a dull tool with a new one in the middle of a job. The TT-1 is completely automatic. Press "measure" and the tool will automatically touch off the TT-1 and set the tool height offset in the tool library. See the TT-1 in action on our Video CD. The TT-1 plugs into the control. See the video.

Remote MPG handwheel allows you to jog an axis one step at a time. Selectable x1, x10, x100 movement per increment. .0001" per increment is the finest increment. Great for touching off and setting up tools and part zero positions on large machines. Tough ABS plastic body with individual selection knobs for each axis and increment amount. 100 pulses per revolution for fine control. Ergonomic design that is easy to hold. Come with convenient hanger which can be mounted on the control or anywhere it is convenient to store the handwheel when not is use. See the video.

Makes setting up tools and jobs on large machines fast and easy.

Ready for delivery, our Rotary Table packages are very price competitive and include: servo motor, servo drive, 4th axis prewire cable, and 4th axis software. Available in AC or DC configurations. True 4th axis contouring and indexing. Click here for more information and pricing.

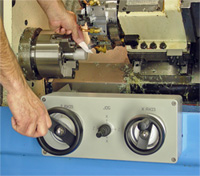

Intuitive handwheels provide the operator with a fast and easy way to setup a job. Move an axis just like a manual lathe. Great for touching off part zero positions and setting up tool offsets these CENTROID handwheels have a natural feel and can be used in conjunction with the axis Jog buttons on the operators control panel. A center mounted Joy stick allows for easy fast jogging of both the X an Z axis in both directions. The CENTROID dual handwheels can be mounted anywhere on the lathe with the provided sealed mounting box or the flaceplate mounted wheels can be mounted flush into your existing cabinet. For both new and retrofit applications. (Part#10787)

The "DC single" makes it easy to add on a 4th axis to an existing three axis control such as the M-40, M-39S and M-400S. The DC single is designed specifically for adding an extra rotary or linear axis to a CENTROID CNC control equipped with a Servo3I/O and DC3IO. The DC single can also be used as a stand-alone single axis DC servo motor drive and has a max output rating of 15 amps, which runs up to a 40 in-lb continuous-rated DC servo motor. As with all our drives, the DC single is digital and is autotuning, there are no trim pots to adjust. Tuning servo motors now takes only a minute. call for more info.