Centroid CNC Components and Accessories

All-in-one Touch Screen CNCPC

- Preloaded with Windows 11 and pre-configured for CNC PC duty

- Preloaded Centroid CNC software with G code Editor, Intercon, Stock PLC programs, Acorn Install Wizard, Touch Screen Operator Control panel.

- 23 or 24" Touch Screen,8 GB ram, Solid State Hard Drive.

- A processor that meets Centroid Min. Requirements

- Wifi, Ethernet, webcam with mic, card reader, usb ports

- Powercord, Keyboard, Mouse

- Centroid tested and pre qualified to work with Centroid CNC controllers

- Compatible with Acorn, AcornSix, Hickory, Oak, and Allin1DC

- Model, Specifications and COLOR may vary.

Note: There are NO VESA mounting holes on this unit.

Centroid NUC CNCPC for use with your Touch Screen LCD display

Centroid NUC CNCPC

- Allows use of any size and type LCD Touch screen or regular LCD monitor.

- Higher Performance PC than the the above Allin1PC

- Intel SSD for the best performance

- Preloaded with licensed copy of Windows 11 and Windows is pre-configured for CNC PC duty

- Preloaded Centroid CNC software Mill and Lathe (free version).

- G code Editor

- Intercon Conversational

- Stock PLC programs

- Touch Screen Operator Control panel.

- Intel I3 processor, 4GB ram, SSD (solid state drive)

- Display port, HDMI, Ethernet, USB

- Centroid tested and pre qualified to work with Centroid CNC controllers

CENTROID Wireless MPG CNC control pendant

Model: WMPG-6 (PDF download)

Add to CartTake the control to where the work is! A game changing tool, the Centroid Wireless MPG handwheel CNC Control pendant allows the operator to conveniently and precisely set up jobs and tools remotely. No software or drivers to install. Plug and Play with Centroid CNC12 Pro CNC software, just plug in the included USB transmitter/receiver and start using it! Perfect for all types of Mills, Lathes, Routers and other specialty CNC machines. click here for more info.

Centroid CNC Operator's Console, Mill or Lathe versions with or without CNCPC

Note: Optional MPG Shown in photo with Console

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Allin1DC, OAK and MPU11 systems. (not compatible with Acorn)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

Available with built-in CNCPC or without CNCPC.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console. )

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Optional pre assembled "Console to Electrical cabinet cable in conduit" Standard size: 16' cables with 6' conduit. (part# 11028) Call or Email us for custom lengths not shown.

Centroid Console Mounting Hardware

Make your own Console mounting hardware or purchase ready to go CNC console mounting hardware kits

Operator Console Floor Stand

- Adjustable Console Height and Angle Articulation

- Vesa Standard 200mmx200mm mount

- Heavy Duty Steel Construction

- Locking Floor Casters

- Optional Utility Tray and Mouse tray

Operator Console Arm Hardware Kit

- Mounts Console to Machine Tool

- Swivel joints at both ends

- Top or Bottom console mount

- Flexible mounting options at Machine end

- Heavy Duty Steel Construction

- Smooth 90 degrees console swivel rotation

- Through Arm control cables chase

- Integral Left/RIght Level Adjustment

- Optional Utility Tray and Mouse tray

- Made in USA

Adapt to existing arm hardware kit (#14752)

This is the same hardware used on our Arm mounting kits and allows the installer to use an existing console support arm by adapting Centroid CNC console mounting hardware to that existing arm using this kit.

This hardware bolts to the existing arm adn mounts to the Centroid M400/T400 CNC consoles allowing smooth swiveling action with adjustable resistance. Popular on retrofit applications or when the integrator wants to create their own console support system.

Centroid CNC Operators Control Pendant (#11077)

Centroid CNC software allows operator machine control through a number of different methods.

This Operator's Control Pendant is for when hard buttons are preferred over touch screen controls. Useful on large and small machine tools alike when setting up parts, fixtures and tools, the pendant allows the operator to take the controls to where the work is. Steel case with magnets on the back and rubber handles, this control pendant uses the same operator control panel found in the M400/T400 CNC console.

The control panel can be removed from the pendant and flush mounted in your own console enclosure as well.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The touch screen VCP is included with Centroid CNC control software CNC12 v4.12+ and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Made-in-USA Centroid DC Servo Motors. Smooth, Powerful, Reliable, Cable and Encoder pre installed, tested ready to run

- Made in USA

- Windings specifically designed for torque characteristics needed for machine tool use

- Advanced ferrite long life brushes

- 180 VDC max voltage allows direct rectification of 110 vac so no transformer is needed

- 29 and 40 in-lb sizes are Nema 42 for compatibility as replacement motors on a variety of machine tools

- Centroid installed encoder and cable

- Centroid Tested and ready to run

- Backward compatible with older Centroid CNC control systems

- Available sizes: 10 in-lb, 16 in-lb 29 in-lb, 40 in-lb and 40 in-lb with brake

- Used on a wide variety of machine tools from knee mills, bed mills, lathes, VMC's,

Routers, and other specialty CNC machinery

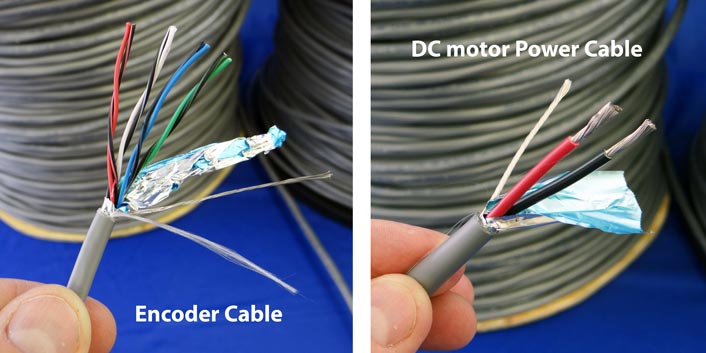

Plug and Play Centroid DC Servo Motor Power and Encoder Cable

Typically used for replacement or retrofit upgrade of an existing DC servo motor for use with the Allin1DC CNC controller. You can make your own cables or buy these ready to go units to save time. High quality Cable with Polyurethane jacket, Color coded encoder cable is twisted pair with Shield and Drain for proper noise immunity. Power cable is high quality stranded copper with proper terminals at both ends for plug and play use with the Allin1DC. Both cables have thick rubber liquid tight strain relief seal at the motor end.

Custom Lengths over 20' available on a made to order basis.

Plug and Play Centroid DC Servo Motor and Spindle Encoder Cable compatible with Allin1DC and Acorn (part #10830)

Choose between two stock lengths, 12 foot and 16 foot. These cables use twisted pair made-in-USA wire and are properly shielded and grounded for reliable encoder signal and are built and assembled by Centroid in the USA.

( If a longer cable is required, we suggest purchasing the bulk encoder cable offered below.)

These cables are commonly used when upgrading DC servo motor encoders for use with the Allin1DC CNC controller. These cables can also be used for spindle encoder applications on both the Allin1DC and Acorn CNC controllers. One end of the cable is a DB9 connector which plugs directly into the Allin1DC or Acorn CNC controller, the other end of the cable is a single row flat pin connector (9 pin C-grid connector) which plugs into the Centroid Encoder pig tail mating connector.

A mating 9 pin C-grid connector and pins are optional with this cable for the case when a non Centroid encoder is used. The optional mating 9 pin C-grid connector can be installed on the non Centroid encoder pig tail wires which then allows the encoder to plug directly into this cable with no soldering or cutting of this cable.

Centroid Servo Motor Cable "Direct Wire" Seal and Strain Relief Cap (#5031)

For use with Centroid motor cables, this direct wire cable strain relief makes a water/oil tight seal against both the motor power and encoder cables to any flat surface. Very useful when converting both old and new servo motors to a direct wire configuration as seen on this page.

Centroid part# 5031 (aluminum cap, gasket, 6-32 screws)

Centroid DC1 single Axis DC servo drive (#11112)

Add a 4th, 5th, and/or 6th Axis to the Allin1DC with the DC1 single axis digital servo drive

The DC1 axis add-on servo drive is designed with simplicity in mind. The drive is a plug-n-play addition to the Allin1DC CNC control board. This drive can be used for rotary or linear axes.

- Includes 4th axis software and programming capabilities.

- Digital Communication between Allin1DC and the DC1.

- Additional DC1's simply Daisy Chain with one another back to the Allin1DC

- The communication cable is included (not shown)

- Connect up to three DC1's to an Allin1DC CNC control board

- Allows the Allin1DC to become a 4 axis, 5 axis or 6 axis CNC control

- Made in USA

PLCAdd1616 I/O expansion board. Add on additional Inputs and Outputs (for use with the Allin1DC or Oak CNC controllers) (#11025)

- Add an additional 16 optically isolated inputs and 16 relay outputs to the Allin1DC and Oak CNC controls

- Plug and Play, PLCAdd1616 to Allin1DC and Oak communication cable included.

- Typically used to control an Automatic Tool Changer

- User definable inputs and outputs

- User configurable, commanded by the Allin1DC/OAk PLC program

- PLCAdd1616 user manual

- Made in USA

Add4AD4DA expansion board. Add an additional analog to digital inputs and digital to analog outputs (for use with the Allin1DC or Oak CNC controllers) (11141)

- Add additional 4 analog to digital inputs and 4 analog to digital

- Plug and Play, Add4AD4DA to Allin1DC/Oak communication cable included

- Typically used for multiple spindle machines tools with individual VFD's for each

- User configurable, commanded by the Allin1DC/Oak PLC program

- Add4AD4DA user manual

- Made in USA

Encoder/Scale expansion board. Add 6 additional encoder ports to the Oak CNC controller. (part# 13085)

- Add additional 6 Encoder or Scale ports to an Oak Board or the Allin1DC

- Plug and Play, Encoder Expansion board to Oak/Allin1DC communication cable included

- Typically used for multiple MPG or Scale inputs.

- User configurable

- Encoder Expansion Board user manual

- Made in USA

Estun AC Brushless Servo Motor, Drive and Cables packages

Yaskawa Sigma 5 and 7 Motor and Drive packages. (for use with the Oak or Acorn CNC controller)

Please call or email sales@centroidcnc.com for a quote! 814-353-9256

For new machine tools, retrofit upgrades or as replacement motors. Yaskawa's are high quality, long lasting, powerful servo motor and drive packages.

see more Yaskawa motors an drives, prices and part numbers on this page..

Yaskawa Servo motor dimensional drawings

Call or email for pricing on larger sizes

Yaskawa to Acorn setup instructions

Yaskawa to Oak setup instructions

YaskawaSigmaWin configuration software download.

Oak Board to Servo Drive communications cable

Communications cable that connects a servo drive to the Oak CNC controller. One end plugs into the servo drive the other end plugs into the Oak CNC control board. Sold in 4 variations. Made in USA.

1.) Yaskawa. Works with Yaskawa Sigma 1,2,5,7 Servo drives

2.) Delta ASD-A or ASD-AB

3.) Flying lead. Servo drive end of cable is left "flying lead" so user can mount any kind of connector necessary to connect to a drive other than Yaskawa, Delta or Estun.

4.) SureServo2

*Yaskawa cable shown, two wire plug is load feedback plug specific to Yaskawa

DC Servo Motor Upgrade/Replacement Encoder kit

Commonly used to upgrade old existing DC servo motors to be compatible with the Centroid Allin1DC. see this web page with photo pictorial showing a typical servo motor encoder upgrade. Replaces Tachometers, Resolvers and Low resolution Encoders. Upgrade existing DC servos to the latest technology for silky smooth closed loop CNC operation. Centroid stocks these high resolution, 5vdc, quadrature differential encoders in several commonly found shaft sizes. Encoder to Encoder cable pigtail included which allows plug and play compatibility with Centroid Encoder Cables using the 9 pin C-grid connector, No crimping or soldering needed. Please measure the servo motor encoder shaft diameter before ordering. More technical how to information on Encoders here..

Note: 10,000 line (40,000 count per revolution) encoders are commonly used on tall pitch machine tools like CNC routers and Linear rail machines to maintain a good encoder counts per inch of linear travel on the machine tool for smooth operation.

High Resolution Servo Motor Upgrade/Replacement Encoder kit for use with AC or DC servo motors

Encoder with pigtail connector. Commonly used on New and to upgrade old existing AC servo motors. Replaces Tachometers, Resolvers and Low resolution Encoders. Also used to upgrade existing DC servos to the latest technology for silky smooth closed loop CNC operation. Centroid stocks these high resolution, 5vdc, quadrature differential servo motor encoders in 8mm shaft size. Encoder to Encoder cable pigtail included which allows wiring to a mill connector or to a 9 pin C-grid connector for DC applications for compatibility with Centroid Encoder Cables, 8000 RPM maximum. Please measure the servo motor encoder shaft diameter before ordering. More technical how to information on Encoders here..

Note: 10,000 line (40,000 count per revolution) encoders are commonly used on tall pitch machine tools like CNC routers and Linear rail machining center machines to maintain a good encoder counts per inch of linear travel on the machine tool for accurate smooth operation.

Power Supplies

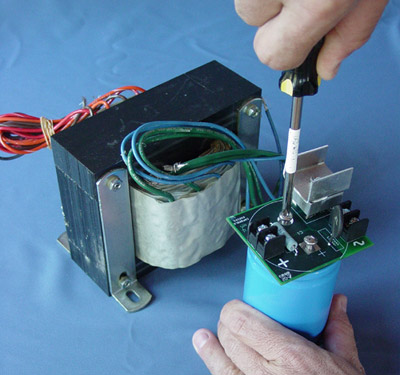

DC Servo Motor Power Supply 110 VAC to 117 DC volts #10537

Add to Cart

- Input 110 - 120 VAC

- Output 117 DC

- Easily powers up to four 29 in-lb DC servo motors

- Kits includes Step Down Transformer, Capacitor, Bridge rectifier board.

- For use with Servo motors with max voltage ratings higher than 117 VDC

- Commonly used in retrofit upgrades when reusing existing servos that have max voltage ratings in the 120 to 145 DC volt range

DC Servo Motor Power Supply 220 VAC to 117 DC volts #10010

Add to Cart

- Input 220-240 VAC

- Output 117 DC

- Easily powers up to four 40 in-lb DC servo motors

- Kits includes Step Down Transformer, Capacitor, Bridge rectifier board.

- For use with servo motors with max voltage ratings higher than 117 VDC

- Commonly used in retrofit upgrades when reusing existing servos that have max voltage ratings in the 120 to 145 DC volt range

Centroid's "Cap and Bridge Combo" DC Servo Motor Power Generator. (12726)

DC Servo Motor "Cap and Bridge Combo"

Add to CartDirectly rectify 110/120 VAC to produce 155 DC volts for use with Servo motors with max voltage rating higher than 160 VDC, (no step down transformer for motors rated above 160 VDC max, use a step down transformer for motor rated under 160 VDC).

- Easily powers up to four 29 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Pre assembled ready to use

- Commonly used for both new cnc control installations and retrofit upgrades

- For use with DC servo motors which are rated above 160 VDC max volts (such as Centroid DC servos) when not using a step downtransformer.

- Use a step down transformer in conjunction if lower DC voltage output is needed for use with lower max voltage rated DC servos.

Power Conversion Examples:

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

Please see this DC Servo motor power discussion for more informationDC Servo Power Supply Bridge Rectifier (10674)

Designed to bolt to at least a 12,000 MFD 250 Volt Capacitor (larger is ok), this printed circuit board rectifying bridge includes the diode bridge, in-rush limiter, bleed down resistor and terminals for AC power in and DC power out. The distance between centers of the capacitor terminal is 1.125in. 600 V, 35 A

AC in one side DC power out the other couldn't be more simple. Made in USA

Used to rectify AC to DC for Servo Motor Power use.

Power Conversion Examples:

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

- AC volts IN x 1.41 = DC volts out

- Requires a 12,000+ mfd or higher rated capacitor

- Bolts to standard size capacity with 1.125" terminal spacing

- Can also be wired to a capacitor, rather than bolt on

- Use with your own Capacitor

- 600 volts max, with 35 amps rating.

Quencharc (aka "Snubbers") is a critical component noise suppression device that is required on all Contactors, Solenoids and external Relay coils, Note: minimum order = qty. 3. (#1819)

Designed for noise suppression of all contactor, solenoid and relay coils to prevent interruption of CNC control communications. One Quench arc should be installed across each coil used in any CNC system.

Contactor in photo not included, Image shows typical Installation of Quencharc across a contactor coil.

Quencharcs are commonly used on all sorts of accessory coils, such as Flood Pump, Mister Solenoid, Vacuum Solenoids, Dust Collection motor starters, Estop Contactors and any other device controlled by a Contactor, Relay or Solenoid.

Tech Bulletin on how to use Quencharcs (aka Snubbers) for Noise Suppression.

DC Servo Motor Power and Encoder Cable sold by the foot. Make your own cables using the same high quality cable we use

DC Servo Motor Power Cable (#1753) For use with 40 in-lb DC Servos and smaller. This is the same high quality 14AWG shielded made in USA wire used in the Centroid Motor/Encoder cable sets listed above. Cable is made with a tough polyurethane jacket. We offer it here for those that want to build their own cables. Motor Power Cable is lso sold in custom lengths per foot, call or email us. Made in USA

DC Servo Encoder Cable (#1754) This is the same high quality,made in USA 22AWG shielded, twisted pair with drain wire used in our pre-built ready-to-use DC servo motor cables listed above. Cable is made with a tough polyurethane jacket. Also sold in custom lengths, call or email us. Connectors available separately below. Made in USA

DC Servo Motor Power and Encoder Connector Kit (13017)

Motor and Encoder Cable Mating Connectors (13017)

Add to CartMake your own DC servo motor power and encoder cables using this connector kit. connectors for both ends of the cables. Power cable connects to servo motor connectors, power cable connects to Allin1DC. Encoder cable connects to encoder pigtail connector and encoder cable connects to Allin1DC connector.

Electrical Cabinet Cable Management System with integrated strain relief. Allows all CNC cabling to enter cabinet through one hole. part #14618

Save time and eliminate expensive fussy cable bulk head connectors with this Centroid Electrical cabinet cable entry management system. This invention allows all the CNC cabinet cables to enter the cabinet thru one rectangular hole in the bottom of the cabinet. The system both seals and supports and organizes the cables.

This system eliminates having to drill many holes in the cabinet significantly reducing cable installation labor and connector costs. Also this system make for a more reliable electrical cabinet with less holes in the electrical cabinet that means less chances for dust, chips, dirt , fluids to enter the cabinet and potentially damage the CNC electronics. With this system it is easy to add or remove a cable with no holes to drill or cover up after a cable addition or subtraction. Reusable and resealable any number of times. Installation is easy simply cut one rectangular hole in the bottom on the cabinet and 4 mounting holes and all necessary CNC cables can be installed using this one entry point. Made in USA, Steel construction with Poron sandwich. 10.5" long.

Industrial quality Estop Button with 2 contact closures #14534

- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, Allin1dc and Oak CNC control boards.

- Thru Hole Panel Mount

KP-3 CNC touch probe

Part, Vise and Fixture Probing: Automatically Set Zero points fast and accurate.

Use the KP-3 probe to quickly and accurately find zero points on a vise, fixture or part. Eliminate operator error when setting zero points, finding edges, or center locations of bosses or bores, slots and webs. Eliminates the need for a centerfinder or an edgefinder. You'll never have to spend 30 minutes using a center finder to locate the center of a bore again. The probe will find and set the center of a bore in just seconds. In addition the probe can be used to verify part dimensions and locations and many other applications. The KP-3 mounts in any 1/2" tool holder and has concentric adjustment screws. Patented and Made in USA. click here for more info and video on the KP-3

KP-3 Acorn kit part# 14946

- KP-3 probe

- 2.5 mm x 40mm carbide stem, ruby tipped stylus

- Stylus wrench

- KP-3 to Acorn cable

- KP-3 Users Manual

- KP-3 to Acorn schematic

KP-3 Oak/Allin1DC kit part# 14944

- KP-3 probe

- 2.5 mm x 40mm carbide stem, ruby tipped stylus

- Stylus wrench

- KP-3 to to bulkhead cable

- Bulkhead to Oak/Allin1DC cable

- KP-3 Users Manual

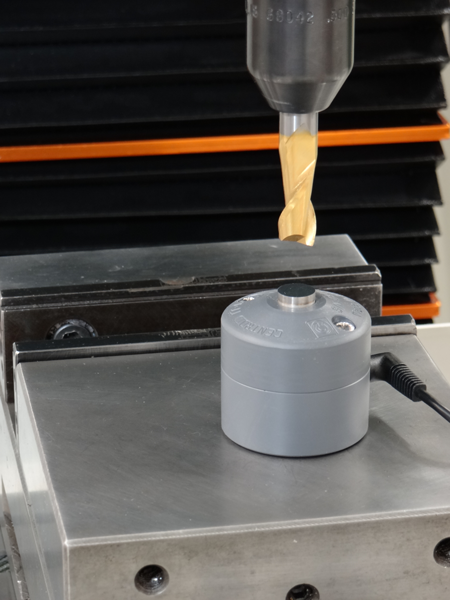

TT-1 CNC Tool Height Measurement Device

- Set Tool Lengths automatically

- Ultra accurate non-conductive kinematic design

- Save time, increase accuracy

- Magnetic base or hard mounts (T-nut or Shank)

- Works w/ CENTROID & most other CNC’s

- Easy to achieve high precision measurements

- Designed for milling and lathe applications: Kneemills, Bed mills, Machining centers and Routers,

Lathes, and Turning centers

- In process tool reset for worn out or broken tools

- Requires conductive tools

- Servicable unit

- Auto cable detection