Mori Seiki Turning Center CNC Control Rerofit upgrades, replacement parts, service

BB, SL-0, SL-1, SL-2, SL-3, SL-5, SL-15, SL-20, SL-25, SL-35, ZL-45, TL series, LL series

The entire line of Mori Seiki Turning Centers are fantastic machines. Robust designs that produce great finishes and are reliable. Mori Seiki used quality ballscrews and bearings throughout along with heavy duty casting design, these machines are classic profit centers. Now the old Yasnac and Fanuc controls are hard to use and parts are getting expensive and you can't find anyone to work on them for a reasonable cost so its time for a CNC control retrofit upgrade!

T.L Hiner in Houston TX produces compressor valve parts with a pair of Mori Seiki Lathes and SL-3 and a TL-3, they positioned the machines facing each other so one operator can run both machines at once. Terry Ruppe, of Arrow Controls of Fulshear, TX installed the new Centroid T-400 CNC controls on both machines. Shane the shop floor manager, says these are two of five Centroid equipped machine tools that they put to work everyday.

Mori Seiki SL-1, SL-4 and SL-5H Turning Center CNC Retrofits at Northwest Machining Services

Northwest Machining Services in Houston, TX has three Mori Seiki's retrofitted with Centroid T-400 CNC controls. An SL-1, SL-4 and a SL-5H. Terry Ruppe of Arrow Controls, performed the retrofit upgrade service on these machines as well.

During the retrofit upgrade, Terry installed a new AC spindle motor and drive in the SL-5H and a larger chuck. The original DC spindle motor was upgraded to an new AC spindle motor to gain more power. New AC spindle motors have more power density than the old DC motors, so you can fit a new AC motor in the same space as the original DC motor and gain spindle HP at the same time. This allows larger parts to be turned on the machine and heavier cuts to be made.

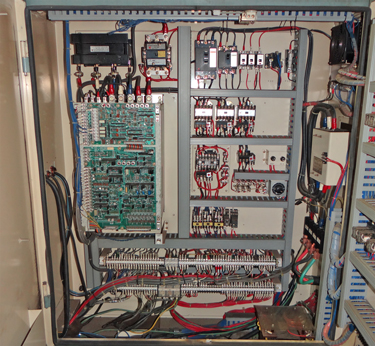

On the left is the stock SL-4 electrical cabinet after the retrofit showing the new Centroid MPU11 and GPIO4 CNC control cards stacked in the middle of the layout. Yaskawa axis motor servo drives in the upper left. Circuit breakers in the upper right and stock terminal strip at the bottom and various power supplies. Clean and simple installation. Below you see the stock spindle drive and contactors and relays for various machine functions being retained simplifying installation.