Extended CNC Work Coordinate Systems: WCS 18 Unique Zero Locations

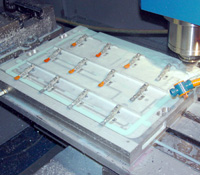

Our exteneded WSC option adds 12 more positions to the standard 6 position WCS for a total of individual part zero positions. Each zero point can be adjusted at any time. The control remembers the positions so there is never a need to reset, even in the event of a power loss. Many uses, this feature allows you to have multiple zero locations in memory. Each vise or fixture can have its own zero point. With WCS you can interupt a job run, set another vise up on the table with new zero, machine that job and return to the original job all without distrubing your original zero point. this is just one example of a time saving use of WCS.

See the Video...

You can call a WCS from within a G code program or use the easy setup menu to switch between any WCS. Use the fill in the blank setup screen to set zero points at any of the 18 WCS location. Also simple table format allows you to Tweak-in part positions by making adjustments to the WCS at any time. Simply add or subtract the amounts needed to move the WCS, therefore eliminating readjusting the setup saving time.