M-39 CNC Retrofit Control for Milling machines, Routers, Plasma, Water Jet, Engraving, Knee Mills

Complete CNC systems for New and Retrofit Installations. Perfect for upgrading older Anilam, Dynapath, Fanuc, Allen Bradley, Cincinnati, GE, Prototrak, Bandit, Hurco, and many other NC/CNC makes.

Upgrade your machine with a CENTROID CNC retrofit and you'll save thousands of dollars in repair costs annually and significantly reduce machine downtime, eliminate expensive repair costs and make profitable parts quickly.

Check List for fast simple CNC control integration

- Complete running CNC control system ready to bolt on a machine tool.

- 1 to 2 day install on most machines.

- Windows 10 OS, Ethernet connection between PC and CNC control.

- Fast, reliable Solid State Hard drive. (no moving parts)

- Prewired servo motors and encoders.

- Servo Motor Drive programmed and wired.

- Control Power supplies provided and wired.

- PLC pre-programmmed and wired, w/extra outputs.

- CNC PC w/software pre-installed w/fiber optic communication.

- Built specifically for your machine:

Motor sizes, cable lengths,

voltages, accessories cables, mounting hardware and more.

- Sealed electrical enclosure, prewired

tested and ready to use.

- Display and operators pendant mounting

hardware

included, multiple configurations

for custom applications.

- Lube,Mist, Flood,Vacuum, Spindle, and custom use contactors/relays

provided and wired ready to use*

- Remote operator control pendant, plug and play control of

spindle, jog axes, tool check, e stop, feed hold, coolant

- Pre-programmmed key functions for common machine tool operations

along with custom user defined key functions.

- User friendly Tool and Part setup menus.

- G code backplot graphics with time estimation.

- Money making options you can add at any time such as:

Digitizing, Probing, Auto tool measurement,

Coordinate System Rotation,

Work Coordinate Systems and more.

- Factory Tested and Run-in, ready for installation as shipped.

- One year warranty, on-site installation and training available.

Start making parts now! Bolt on installation for both new and retrofit applications

New M39S Windows 10 PC based CNC console

The M39S now uses CENTROID's new ALLIN1DC CNC control card along with a new Windows10 All-in-one PC running our reliable CNC12 software. Now you get a big screen and keyboard with built in mouse pad and all the advantages of Windows 10 with all M39S orders with no price increase over the previous model.

This new combination yields many advantages and useful tools to make your CNC jobs easier and faster to complete. In addition to all the great features of the CENTROID CNC software you get:

- Windows 10 familiarity for easy file transfers and networking

- Large easy to read display, (touch screen available).

- Run Windows compatible 3rd party software tools on the control such as G code editors, CAD systems, CAD/CAM systems etc.

- Use any PC compatible keyboard or mouse.

- Background editing, run another program while the machine is running a job

- Internet based remote control for fast accurate tech support

- Fast reliable Solid State Hard drive (no moving parts)

Complete CNC control is assembled and factory tested ready to install

We build the CNC so you don't have to. Not just a box of parts or a software disc like the other guys, our CNC controls are ready to install on the machine, each M39 is custom built for your application, all servo motors, power supplies, PLC programming, CNC PC and Software are shipped assembled and ready to run. Get down to business fast and start making profitable parts right away, no other CNC control saves you this much time on installation. Since the M39 is a running CNC control as shipped, the installation is just a matter of bolting up the control, installing the servo motors, and connecting the power.

The M39 can drive either AC or DC servo motors up to 8 axes. The complete wired electrical enclosure can be mounted to the machine or with the CENTROID stand shown. Monitor and keyboard along with the pendant dock allow for easy machine adaptation and customization. Hardware provided makes installation quick and simple. The M39S CNC system is powered by standard 110 VAC or can be ordered in a high power version for 220 volt single or three phase or 440 volt phase input applications.

Advanced M39 CNC Features make you money

Useful Tools for quicker job turn around.

Dedicated control panel for all common Milling functions

Conversational Programming is fast and easy

CAD to CNC, DXF file import with Intercon Conversational

Convert DXF files into G code with CENTROID's

Intercon conversational programming software. NO CAD/CAM system necessary.

Fast and simple, this new feature allows you to create parts directly

from a CAD file on the control or on your desktop PC. You can even

combine any or all of your CAD file with any conversational events.

This is the most flexible way to take advantage of both CAD/CAM like

programming with the simplicity of conversational. With a fast learning

curve anyone can be producing money making parts from a DXF file in

short order. This new feature saves you both time and money, less expensive

than a CAD/CAM system, much easier to learn with faster results.

Click here for more CAD to CNC info.

5 Axis CNC control. True simultaneous 5 axis machining

True 5 axis machining is now available. Smooth consistent 5 axis motion. Great for either gimble table setups or knuckle head machines. X,Y,Z,A and B motion all at the same time or in any combination. For Milling machines and CNC routers. Note: The M-39 can control up to 8 axes simultaneously.

Auto tool changer

The CENTROID CNC control can operate a wide variety of types of tool changers. Umbrella type to Swing arm -- the Centroid provides fast repeatable tool changes. Automatic batch measurement is also available when used with our TT-1 Auto Tool Setter. Just highlight the tools you would like to measure and the batch feature will automatically retrieve, measure and replace each tool automatically.

Rigid tapping, Deep hole tapping and Threadmilling

With a CENTROID M39 you can make all kinds of threads.You can use Tapping, Rigid Tapping and Threadmilling depending on your part for the best result! CENTROID's advanced rigid tapping is simple to program and will both tap a hole in the regular way AND can also use the deep hole cycle to make a large diameter thread. Deep hole tapping taps a hole much in the same way as you would by hand. It allows you to tap a much larger hole than the HP of your machine would normally allow!

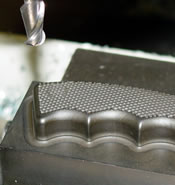

Digitizing: Turn your milling machine into a copy machine.

Copy and Cut 2D and 3D shapes. Centroid's affordable, effective Digitizing is the simplest CNC Digitizing on the market. Just record and play back. Do you have a 2D contour such as a CAM or a 3D part like a mold or plug? But no print? Let our Digitizing feature copy the part for you. Digitizing turns your milling machine into a copy machine. Centroid has overcome the cumbersome problems associated with Digitizing on other controls. With a Centroid, it's actually one of the simplest features on the control to use. With our Digitizing feature you will be able to copy and reproduce an existing shape with little or no programming! No CAD/CAM necessary, however you can export the Digitizing information to a CAD/CAM system for further modification. It's very popular for repairing cylinder head combustion chamber damage, copying cams, creating molds and plugs from existing objects and many other uses. more...

Auto tool set

Setup your tools in a quarter of the time it would normally take! If you often machine short-run parts and are always setting up and tearing down for a new job, the TT-1 Auto tool set will save you tons of time while more accurately setting your tool height offsets. With the TT-1 you can create more parts per hour since the tool set up is so much faster. You'll even save time when you have to replace a dull tool with a new one in the middle of a job. The TT-1 is completely automatic. Press "measure" and the tool will automatically touch off the TT-1 and set the tool height offset in the tool library. See the TT-1 in action on our Video CD. The TT-1 plugs into the control...

Fully sealed, coolant-proof, optional Keyboard

With any CENTRIOID CNC control you can use a regular PC keyboard or our fully sealed unit. We found that about half our customers prefer a regular open style PC keyboard and the other half prefer a sealed unit. The CENTROID sealed PC keyboard is liquid-proof and provides reliable and durable keyboard operation in a shop environment.Our keyboard is: fully sealed, coolant proof, long lasting in shop environment, has tactile feedback, and has raised buttons with distinct action. Click here for more info.

Retrofit CNC Kits for Routers, Plasma, Knee Mills, Bed Mills and many more specialty machines.

Good iron? Obsolete control? Time for a CENTROID Retrofit! Turn your Milling machine into a money-maker with a modern Centroid CNC control. Our complete turnkey retrofit systems are prepared for your specific machine, making retrofit installation times much faster. Machining performance is better than new, programming is now faster and simpler, and maintenance costs are virtually eliminated. How much money per year are you spending to keep your old control alive? Don't throw away your money when you could have a new reliable Centroid CNC installed (with training) for less than the cost to keep on an old CNC alive. The Centroid retrofit upgrade is also much less than the cost of buying new. Click here for more retrofit information.

M-39 CNC control brochure download

Click here to download the M39 brochure in pdf.

CENTROID CNC Service and Support

Remote control from the factory, Skype video and instant messaging.

Centroid CNC controls have a proven reliable track record and offer cool, quiet operation. Our controls are easy to maintain, with autotune, dragplot and self diagnostics. Centroid CNC users are supported by a nation wide network of local Factory Trained Technical Representatives who provide fast affordable service, training and upgrades. Centroid users can stay up with current technology with easy Centroid CNC software updates. In just minutes, new CNC features can be added to the control.

Powerful control with user-friendly operation