Centroid "Hickory" CNC Controller

This is a legacy page, to view up-to-date information and pricing please visit the Hickory Page on ShopCentroidCNC.com

Centroid "Hickory" EtherCat based closed loop CNC Controller.

A reliable, high performance, industrial quality CNC control. Hickory utilizes an integrated Motion Control CPU and communicates with both the CNCPC and the Servo Drives via a fast and reliable EtherCat connection. The Hickory is an 8 axis CNC control board. Perfect for many types of machine tools such as: CNC milling machines of all types, Turning Centers, and a wide variety of CNC Routers and other specialty applications. Typically used on CNC machine tools where a high performance CNC control is needed. Hickory utilizes only approved AC brushless servos with EtherCat communication protocol, compatible drives with Hickory are: Yaskawa Sigma 7, Glentek Gamma series, Estun Summa, Leadshine EL7 and EL8, Inovance SV660N. More makes and models will be added to the compatibility list as we test them. Currently there is no guarantee from Centroid when using Hickory with any other drive other than the Centroid curated drives listed. We are working on Delta at the moment and welcome the opportunity to test others as well.

Hickory significantly reduces electrical cabinet cabling and labor. Hickory is absolute encoder compatible which further reduces cabling, labor and cost to install the CNC control, as well as added convenience to the operators day to day operation in time savings, reduced mistakes and scrap parts due to the elimination of machine homing and resetting of work coordinate systems, the machine always knows where it is at even when the power is off.

Centroid Hickory CNC Controller base kit: Industrial grade DIY EtherCat CNC control board for all types of CNC machine tools.Centroid Hickory CNC controller kit (part # 14924) includes:

- Hickory control board

- Qty. 4 Plug and Play Relay 8 Modules

- Logic power supply with power leads

(50/60 Hz 100-120 VAC and 208-240 VAC input power)

- Connector kit

- 15' Shielded Ethernet cable

- Riser Mounting Pan

- Typical CNC machine tool pre-programmed PLC Inputs and Outputs

- Mill and Lathe Conversational Programming Software

- Installation and Operator's manuals PDF

- Full Size Paper Wiring Schematic

- DIY self-service CNC support through Centroid Community CNC Forum which is Centroid Technician monitored and maintained.

- Centroid CNC12 "FREE" version of CNC software. (Purchase Pro or Ultimate for additional feature set, see below.)

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Hickory, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/Hickory/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Hickory kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Hickory, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/Hickory/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Hickory kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Hickory, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/Hickory/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Hickory kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

See Pro and Ultimate License feature set in comparison table below

If you purchase License at the same time as the Hickory, the License will be sent via E-mail delivery. M-F 8-5 EST USA

Note: Each Software License is specific to a single CNC control (Oak/Allin1DC/Hickory/MPU etc) not the CNCPC

If you are purchasing a license for a previously ordered Hickory kit please email a fresh report.zip file to diysales@centroidcnc.com along with your paypal receipt to expedite delivery.

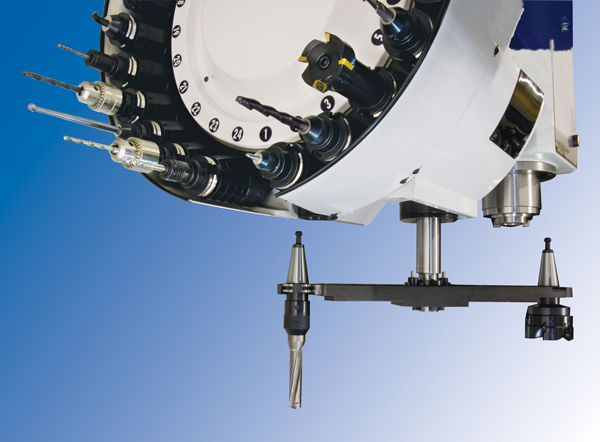

ATC capability plug in for Oak

This plug in is required for Oak system that will be running a Tool Changer. A Mill or Lathe Pro License is required for full ATC functionality.

CNC12 Ultimate Plus for Allin1DC, Oak, MPU11, Hickory

Includes all the features of Ultimate, PLUS 6 axis simultaneous interpolated motion CNC software.

Allin1DC can command up to 6 axis drivers, Hickory and Oak can command up to 8 axis drivers, with or without this option. This option allows: Simultaneous Coordinated Interpolated motion of individual axes involving 5 or more axes which is a regulated technology by the US government. (If you are outside the US we will provide and ask you to sign two documents, a letter of assurance and a letter of certification for our records).

Most users do not require this feature. Don't confuse True interpolated 5+ axis motion with simply having 5 or more drive ports on the CNC control board that all can command and move 5 or more axes. Allin1DC, Hickory, and Oak without this 6 axis simultaneous software is considered a 4+2 system. Which is: Fully interpolated motion for ANY four axis in ANY combination at ANY given time. For instance XYZW, XWAB, ABCW, ZWAB, XYAB, ZYAB, etc..

Software Level comparison

| Features | CNC12 Free v5.0+ | CNC12 Pro v5.0+ | CNC12 Ultimate v5.0+ |

|---|---|---|---|

| Mill and Lathe Intercon Conversational programming | Limited to 20 blocks of conversational | Unlimited | Unlimited |

| Wireless MPG Pendant support *** | Not included | Included | Included |

| G-code program size | Limited to 50Kb Mill , 5Kb Lathe G-code file size | Unlimited G-code file size | Unlimited G-code file size |

| Work Coordinates Systems (WCS) | One (G54) | Eighteen (G54-G59 plus extended WCS) | Eighteen (G54-G59 plus extended WCS) |

| Menu driven Probing cycles | Center of bore | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR |

| Menu driven Digitizing cycles | Grid, Radial, Contour, Wall following, limited to 2500 points | Grid, Radial, Contour, Wall following, limited to 2500 points | Unlimited point Grid, Radial, Contour, Wall following |

| Auto Tool Height Measurement | Unlimited auto measure on: Reference Tool & Tools 1,2,3 |

Unlimited auto measure on all tools. |

Unlimited auto measure on all tools. |

| Coordinate System Rotation | Yes | Yes | Yes |

| Auto find CSR with Probe | No | Yes | Yes |

| Manual find CSR with Probe or Wiggler | Yes | Yes | Yes |

| Manual enter angle for CSR | Yes | Yes | Yes |

| Tool Library | 10 Tools | 200 Tools, (99 Tools Lathe) | 200 Tools Mill, (99 Tools Lathe) |

| Sub Programs and Macros (M98 & G65) Write your own custom macros, many uses | Not Included | Included | Included |

| Cutter Compensation | Included | Included | Included |

| Backlash Compensation | Included | Included | Included |

| Screw compensation (laser or manual!) | Included | Included | Included |

| 3 axis simultaneous | Included | Included | Included |

| 4 axis simultaneous | Not included | Included | Included |

| 4 th Axis linear or rotary conversational programming. | limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate as a 2 axis CNC with Manual Quill | Included | Included | Included |

| Operate as a 2 or 1 axis CNC control | Included | Included | Included |

| Any axis can be Linear or Rotary | Included | Included | Included |

| Spindle Encoder feedback,w/ RPM display | Included | Included | Included |

| Mill Rigid Tapping | Not Included | Included | Included |

| Lathe Threading | Not included | Included | Included |

| Lathe Automatic CSS | Not Included | Included | Included |

| Lathe Rigid Tapping | Not included | Included | Included |

| Lathe C axis | Not Included | Not included | Included |

| Lathe Automatic Tool Measurement | Unlimited auto measure on: Tools 1,2,3 | Unlimited auto measure on all tools. | Unlimited auto measure on all tools. |

| G81 drilling cycles | Included | Included | Included |

| Compression Tapping Gcode Cycles | Included | Included | Included |

| Mill G-code scaling and mirroring | Included | Included | Included |

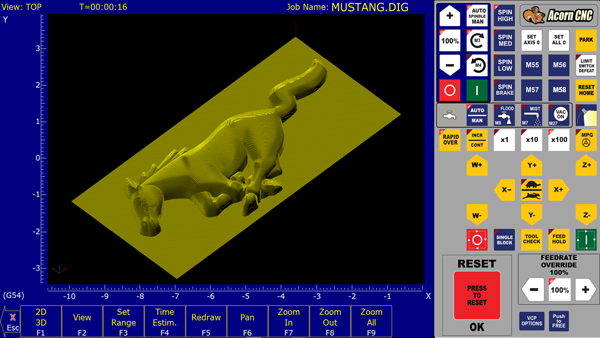

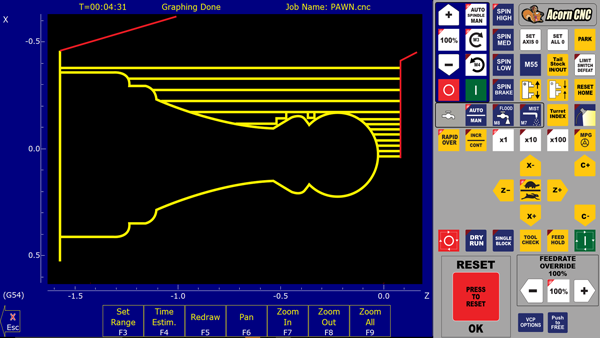

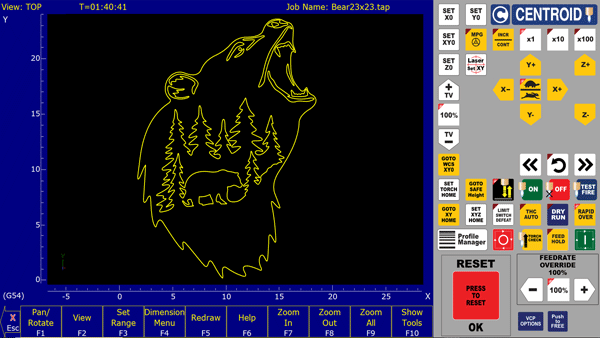

| True G-code backplot graphics | Included | Included | Included |

| Run Time Program Graphics | Included | Included | Included |

| Smart Search (stop and restart at any point) | Included | Included | Included |

| User Configurable Touch Screen Virtual Control Panel ** | Included | Included | Included |

| Backlash compensation | Included | Included | Included |

| Menu driven Part and Tool setup menus | Included | Included | Included |

| Intercon Teach Mode | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Drilling cycles: Drilling, Deep Hole, Chip Breaking | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Pocketing: Circular,Rectangular, Irregular | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Contouring | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Threadmilling | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Conversational Compression Tapping | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Auto Connect Radius | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Lathe Cycles. Auto profile cleanout, grooving, cutoff, chamfer, turning, end face turning, | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Math/Geometry Help | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate in Millimeter or Inches | Yes | Yes | Yes |

| 4th axis Jogging | Yes | Yes | Yes |

| Software Axis pairing. Pair an axes with the 4th or 5th axis. Allows Two axis to be paired axes. | No | Yes | Yes |

| Auto Squaring of Software Paired axis with auto homing | No | Yes | Yes |

| Hardware Axis Pairing | Yes | Yes | Yes |

| 4th axis G-code moves: 4&1,4&2,4&3,4&1&2,4&2&3,4&1&3&4, 4&1&2&3 | No, "Free" is limited to 3 axis simultaneous . | Yes, 4 axis simultaneous movement with full interpolation | Yes, 4 axis simultaneous movement with full interpolation. |

| Scale Input for axis positioning feedback | No | No | Included |

| M0 Jogging | No | Included | Included |

| PLC Detective Software | Included | Included | Included |

| Use one input for all axis Homing | Included | Included | Included |

| ATC support plugin | No | Requires ATC Software Plug-in $280 | Requires ATC Software Plug-in $280 |

| 4 axis Simultaneous G-code moves: | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation. (interpolated moves for any four axes in combination with any others including paired axes.This is 4+2*) | Yes, 4 axis simultaneous movement with full interpolation. (interpolated moves for any four axes in combination with any others including paired axes.This is 4+2*) |

| Simultaneous 5 axis drive moves with one paired axes | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) This is 4+2*. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) This is 4+2*. |

| Simultaneous 6 axis drive moves with two paired axes | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) |

| Five axis or more fully interpolated simultaneous G code moves | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th, 5th, 6th axis moves. | Requires purchase of Ultimate Plus. | Requires purchase of Ultimate Plus. |

These Leadshine EL7 EtherCAT drive/motor/cable packages have been curated by Centroid with extensive testing on various Hickory equipped CNC machine tools at our facility here in Central Pennsylvania USA.

These packages consist of compatible AC Servo Motors, EtherCat Servo Drives and the corresponding Cables you need for your next CNC machine tool project, simply pick the motor size, type and cable length.

- Hickory and these packages provide Absolute Encoder functionality! That means the machine always knows where it is at even when powered off.

- Daily CNC machine homing is eliminated with absolute encoders!

- Any paired axes will always square to each other when powered up.

- Limit and Home switches are optional and unnecessary.

- Daisy Chain connection from Hickory to the EL7 drive and all subsequent drives simplfies cabling installation and reduces both cable and labor costs.

- Utilizes off the shelf sheilded ethernet cables

USA shipments drop ship direct from the Leadshine USA warehouse in California

International Shipments drop ship direct from Leadshine HQ in China

When choosing the motor type note the motor physical size, power rating, useful RPM when sizing to your application.

750 watt (80 mm frame, 3000 rpm, 2.39 N-m cont., 5000 max rpm)

Where the "80 mm frame" refers to the square face frame size of the 750 watt motor. Reference the complete ELM2 servo motor dimensional specifications here.

and the "3000 rpm" refers to the useful, normal RPM range of the 750 watt motor (0-3000)

and "2.39 N-m" is the useful, normal continuous torque output of the 750 watt motor in Newton Meters

and the "5000 max rpm" is the maximum RPM of the 750 watt servo motor, this max rpm can be reached for short periods by the motor as long as the motor load is not excessive. Note: Torque will fall off from the continuous torque rating above the useful RPM, in this example 3000 rpm.

Gear and Size the machine tool kinematics for the desired results (machine max rates, accuracy and power) if in doubt its always best to use the next size larger servo motor/drive package.

Yaskawa Sigma 7 Motor and Drive packages

Please call or email sales@centroidcnc.com for a quote! 814-353-9256

For new machine tools, retrofit upgrades or as replacement motors. Yaskawa's are high quality, long lasting, powerful servo motor and drive packages.

Centroid "USB-BOB" Operator Control Panel Interface Kit

Add to Cart

USB-BOB has been through a 4 month alpha tester program with excellent results.

USB-BOB is compatible with CNC12 v5.19 BETA software (the official release version will be CNC12 v5.2)

Typical Beta to Official release software time table is approximately 6-8 weeks.

More info on the beta software release here.

The Centroid USB Operator Control Panel Interface Board (aka “USB-BOB”) is a CNC machine tool operator control panel interface board that connects to the CNCPC via a USB port. The Operator Control Panel Interface Board is intended to be an affordable, reliable, alternative to traditional methods of building CNC control operator control consoles/panels. The USB-BOB provides inputs for the most commonly used operator controls in a package that installs quickly with minimal fuss saving on wiring/installation labor and CNC controller inputs. It features inputs for three standard rotary encoders with integrated push-button, three MPG hand-wheel encoders, 12 optically isolated switch inputs, and 12 open collector LED outputs. The USB-BOB can be used in conjunction with Centroid’s popular Virtual Control Panel or without.

The USB-BOB is plug and play with preprogrammed button and knob functionality: Many common functions like Cycle Cancel, Tool Check, Feed Hold and Cycle Start along with Rapid Override, Spindle Speed Override and Feedrate Override are preprogrammed and user select-able with easy drag and drop installation.

In addition to these pre-programmed controls, all controls are user configurable through Centroid’s CNC PLC language so user can customize both the button or knob functionality to suit their application and tastes.

Common uses:

• Physical buttons and knobs for core/common operator functions simplifying the design for a hard operator console

• Supplement Centroid Virtual Control Panel with physical controls without using up any CNC control board inputs

• Add separate Rapid Override to Centroid Legacy control systems that did not have this feature.

Centroid "USB-BOB" Operator Control Panel Interface Manual

Note: For Allin1DC and Oak, custom PLC modification is required to support USB-BOB at this time.

- Preloaded with Windows 10 and pre-configured for CNC PC duty

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

- Touch Screen

- Wifi, Ethernet, webcam with mic, card reader, usb ports

- Powercord, Keyboard, Mouse

- Centroid tested and pre qualified to work with Centroid CNC controllers

- Model, Specifications and COLOR may vary.

Note: There are NO VESA mounting holes on this unit.

- Allows use of any size and type LCD Touch screen or a regular LCD monitor.

- Higher Performance PC than the the above Allin1PC

- Intel SSD for the best performance

- Preloaded with a licensed copy of Windows 10 and Windows is pre-configured for CNC PC duty

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

- G code Editor

- Intercon Conversational

- Stock PLC programs

- Touch Screen Operator Control panel.

- SSD (solid state drive)

- Display port, HDMI, Ethernet, USB

- Centroid tested and pre qualified to work with Centroid CNC controllers

WMPG-6 (PDF download)

International shipping is calculated during checkout.

Requires CNC12 v4.16+ and a Pro License

Take the control to where the work is! A game changing tool, the Centroid Wireless MPG handwheel CNC Control pendant allows the operator to conveniently and precisely set up jobs and tools remotely.

Plug and Play with Centroid CNC12 Pro Acorn CNC software and CNC12 for Oak, Red Oak and Allin1DC with the USB MPG software plug-in.

SImple and fast setup. Plug in the included USB transmitter/receiver and start using it! Perfect for all types of Mills, Lathes, Routers and other specialty CNC machines. click here for more info.

KP-3 CNC touch probe

Part, Vise and Fixture Probing: Automatically Set Zero points fast and accurate.KP-3 Oak kit part#14944

- KP-3 probe

- 2.5 mm x 40mm carbide stem, ruby tipped stylus

- Stylus wrench

- KP-3 to bulkhead cable

- Bulkhead cable to Oak

- KP-3 Users Manual

Quickly and accurately setup tool heights in the tool library with a push of a button. The CENTROID TT-4 automatic tool height offset touch probe is plug and play with all Centroid CNC controls. Eliminates gauge blocks, paper, and repeated measurements. Save time and increase accuracy. Fully integrated into the CNC control tool library menu, just select the tool and press auto measure to set the tool height automatically. Makes measuring all types of tools faster and more accurate. Find the longest insert in a multiple insert tool quickly. Once you start using the TT-4 you'll wonder why you waited to purchase this time saving tool. Measure just one tool or a whole group of tools at once. Can also be used in the middle of a job to measure a replacement tool. Integrated with an Automatic tool changer for batch tool measurement. The TT-4 is based on KP-3 touch probe technology and is a robust kinematic design and works with all spindles even ones that with non conductive bearings (ceramic) or tooling that doesn't conduct (diamond).. Acorn CNC software configuration is simple one button press with the pre configured preset for the TT-4 using the Acorn Setup Wizard. Note: Also compatible with most all other CNC controller such as but not limited to: Mach3/4, WinCNC, LinuxCNC, Pathpilot and others.

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Allin1DC, OAK and MPU11 systems. (not compatible with Acorn)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP

Available with built-in CNCPC or without CNCPC.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console. )

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Optional pre assembled "Console to Electrical cabinet cable in conduit" Standard size: 16' cables with 6' conduit. (part# 11028) Custom lengths avalible, please call or email.

Same control panel that is on the M400/T400 CNC consoles but placed in a box with a 20' cord.

Centroid CNC software allows operator machine control through a number of different methods.

This Operator's Control Pendant is for when hard buttons are preferred over touch screen controls. Useful on large and small machine tools alike when setting up parts, fixtures and tools, the pendant allows the operator to take the controls to where the work is. Steel case with magnets on the back and rubber handles, this control pendant uses the same operator control panel found in the M400/T400 CNC console.

The control panel can be removed from the pendant and flush mounted in your own console enclosure as well.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The touch screen VCP is included with Centroid CNC control software CNC12 v4.12+ and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Longer cords up to 50' are available call for quote or just use the Wireless MPG for long distance applications.

- Add an additional 16 optically isolated inputs and 16 relay outputs to the Allin1DC

- Plug and Play, PLCAdd1616 to Oak communication cable included.

- Typically used to control an Automatic Tool Changer

- User definable inputs and outputs

- User configurable, commanded by the Allin1DC PLC program

- PLCAdd1616 user manual

- Add additional 4 analog to digital inputs and 4 analog to digital

- Plug and Play, Add4AD4DA to Oak communication cable included

- Typically used for multiple spindle machines tools with individual VFD's for each

- User configurable, commanded by the Oak PLC program

- Add4AD4DA user manual

- Add additional 6 Encoder or Scale ports to an Oak Board

- Plug and Play, Encoder Expansion board to Oak communication cable included

- Typically used for multiple MPG or Scale inputs.

- User configurable

- Encoder Expansion Board user manual

| Features | CNC12 Free v5.0+ | CNC12 Pro v5.0+ | CNC12 Ultimate v5.0+ |

|---|---|---|---|

| Mill and Lathe Intercon Conversational programming | Limited to 20 blocks of conversational | Unlimited | Unlimited |

| Wireless MPG Pendant support *** | Not included | Included | Included |

| G-code program size | Limited to 50Kb Mill , 5Kb Lathe G-code file size | Unlimited G-code file size | Unlimited G-code file size |

| Work Coordinates Systems (WCS) | One (G54) | Eighteen (G54-G59 plus extended WCS) | Eighteen (G54-G59 plus extended WCS) |

| Menu driven Probing cycles | Center of bore | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR |

| Menu driven Digitizing cycles | Grid, Radial, Contour, Wall following, limited to 2500 points | Grid, Radial, Contour, Wall following, limited to 2500 points | Unlimited point Grid, Radial, Contour, Wall following |

| Auto Tool Height Measurement | Unlimited auto measure on: Reference Too l & Tools 1,2,3 |

Unlimited auto measure on all tools. |

Unlimited auto measure on all tools. |

| Coordinate System Rotation | Yes | Yes | Yes |

| Auto find CSR with Probe | No | Yes | Yes |

| Manual find CSR with Probe or Wiggler | Yes | Yes | Yes |

| Manual enter angle for CSR | Yes | Yes | Yes |

| Tool Library | 10 Tools | 200 Tools, (99 Tools Lathe) | 200 Tools Mill, (99 Tools Lathe) |

| Sub Programs and Macros (M98 & G65) Write your own custom macros, many uses |

Not Included | Included | Included |

| Cutter Compensation | Included | Included | Included |

| Backlash Compensation | Included | Included | Included |

| Screw compensation (laser or manual!) | Included | Included | Included |

| 3 axis simultaneous | Included | Included | Included |

| 4 axis simultaneous | Not included | Included | Included |

| 4 th Axis linear or rotary conversational programming | limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate as a 2 axis CNC with Manual Quill | Included | Included | Included |

| Operate as a 2 or 1 axis CNC control | Included | Included | Included |

| Any axis can be Linear or Rotary | Included | Included | Included |

| Spindle Encoder feedback,w/ RPM display | Included | Included | Included |

| Mill Rigid Tapping | Not Included | Included | Included |

| Lathe Threading | Not included | Included | Included |

| Lathe Automatic CSS | Not Included | Included | Included |

| Lathe Rigid Tapping | Not included | Included | Included |

| Lathe C axis | Not Included | Not included | Included |

| Lathe Automatic Tool Measurement | Unlimited auto measure on: Tools 1,2,3 |

Unlimited auto measure on all tools. | Unlimited auto measure on all tools. |

| G81 drilling cycles | Included | Included | Included |

| Compression Tapping Gcode Cycles | Included | Included | Included |

| Mill G-code scaling and mirroring | Included | Included | Included |

| True G-code backplot graphics | Included | Included | Included |

| Run Time Program Graphics | Included | Included | Included |

| Smart Search (stop and restart at any point) | Included | Included | Included |

| User Configurable Touch Screen Virtual Control Panel ** | Included | Included | Included |

| Backlash compensation | Included | Included | Included |

| Menu driven Part and Tool setup menus | Included | Included | Included |

| Intercon Teach Mode | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Drilling cycles: Drilling, Deep Hole, Chip Breaking | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Pocketing: Circular, Rectangular, Irregular | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Contouring | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Threadmilling | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Conversational Compression Tapping | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Auto Connect Radius | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Lathe Cycles. Auto profile cleanout, grooving, cutoff, chamfer, turning, end face turning | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Math / Geometry Help | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate in Millimeter or Inches | Yes | Yes | Yes |

| 4th axis Jogging | Yes | Yes | Yes |

| Software Axis pairing. Pair an axes with the 4th or 5th axis. Allows Two axis to be paired axes | No | Yes | Yes |

| Auto Squaring of Software Paired axis with auto homing | No | Yes | Yes |

| Hardware Axis Pairing | Yes | Yes | Yes |

| 4th axis G-code moves: 4&1, 4&2, 4&3, 4&1&2, 4&2&3, 4&1&3&4, 4&1&2&3 |

No, "Free" is limited to 3 axis simultaneous | Yes, 4 axis simultaneous movement with full interpolation |

Yes, 4 axis simultaneous movement with full interpolation. |

| Scale Input for axis positioning feedback | No | No | Included |

| M0 Jogging | No | Included | Included |

| PLC Detective Software | Included | Included | Included |

| Use one input for all axis Homing | Included | Included | Included |

| ATC support plugin | No | Requires ATC Software Plug-in | Requires ATC Software Plug-in |

| 4 axis Simultaneous G-code moves | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation. (interpolated moves for any four axes in combination with any others including paired axes.This is 4+2*) | Yes, 4 axis simultaneous movement with full interpolation. (interpolated moves for any four axes in combination with any others including paired axes.This is 4+2*) |

| Simultaneous 5 axis drive moves with one paired axes | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) This is 4+2*. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) This is 4+2*. |

| Simultaneous 6 axis drive moves with two paired axes | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th,5th,6th axis moves. | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) | Yes, 4 axis simultaneous movement with full interpolation.(software paired axes are considered 1 axis as it has one label) |

| Five axis or more fully interpolated simultaneous G code moves | No, "Free" is limited to 3 axis of simultaneous moves with single axis 4th, 5th, 6th axis moves. | Requires purchase of Ultimate Plus. | Requires purchase of Ultimate Plus. |

*** Wireless MPG support for machines NOT using a stock v4.16+ PLC program require their custom PLC program to be edited and tested which requires PLC programming.

** VCP support for machines NOT using a stock v4.16+ PLC program require their custom PLC program to be edited and tested which requires PLC programming.

- Program parts in the comfort of your office.

- Program while the machine is running a job.

- Easy part program transfer from your PC to the control via LAN or USB.

- True G-code backplot graphics, see exactly what the machine toolpath will be.

- Use on the same PC as your CAD system.

- A USB Keylock allows user to install software on as many computers as they want.

- Offline programming USB keylock is shipped the next business day.

- Works with Windows 7/8/10

- Download offline conversational programming software here, offline programming software runs without USB keylock but limited to 20 lines of Intercon. Plug in the USB keylock for unlimited conversational programming operation. Choose "Offline" during the installation process.

Add to Cart

Industrial quality Estop Button with 2 contact closures: #14534

Add to Cart- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, Allin1dc and Oak CNC control boards.

- Thru Hole Panel Mount

Wired MPG #11069

Use the Manual Pulse Generator to jog the machine tool, very useful for part and tool setups. Order with or without internal bulk head cable. If you have a factory built M400/T400 CNC control or if you ordered the CNC console conduit cable kit you do not need to buy the internal bulkhead cable. If you are building a DIY CNC control based on the Oak cnc controller you will need the internal bulkhead cable to connect this MPG to the Oak board.

- 100 pulses per rev

- Axis Selector for 6 axes

- Increment amount selector (user configurable in CNC10/11/12)

- For use with Allin1dc and Oak CNC control boards.

- High quality construction with gold plated connector pins

- Hook hanger mount and magnets on the back of the unit

- Pre configured for use with Centroid CNC10/11/12 control software

- Plug and Play with Oak/Allin1DC cnc controls running CNC11 or CNC12 software

Looking fro an MPG for an older CNC10 system? please email us your system serial number

CNC10 Kits numbers had 5 digits. (Note: if you have a 6 digit Kit number that is a CNC11/CNC12 system)

How to locate serial number.