Centroid Acorn CNC controller Installation and start up guide

Minimum Components and Tools needed to build an Acorn based CNC control:

- Centroid Acorn CNC controller kit

- A updated Windows 10 or 11 PC that meets the Centroid Acorn Minimum CNC PC requirements, see below

- Typical electrical assembly tools, multi meter, wire stripper, screw drivers, crimp connectors, etc.

- Acorn Installation Manual (found on this page that contains all Acorn documentation)

- Centroid CNC controller hookup schematics (click 'search files' and type in "acorn" or "acornsix" to filter the results on this page)

*Warnings*

1.) Do not use the USB port found on the Beagle Bone Motion control CPU. The USB port is used for stand alone Initial firmware installation ONLY. (Centroid CNC12 software will automatically update the BBG firmware so no need to use this port once the BBG is connected to the Acorn) Using this port while connected to the Acorn will cause damage. The Acorn CNC controller communicates with the CNC PC via the Ethernet connection NOT the USB port. The Acorn board is NOT powered thru the USB port. Do not plug anything into the USB port. The Beagle Bone is preloaded with the proper firmware at Centroid and is installed onto the Acorn board and tested before shipping so everything is ready to run. No need for user to install firmware.

2.) Do not de-power the Acorn board while CNC12 software is updating the firmware on the Acorn board. CNC12 software will usually update the firmware on the Acorn Board the first time it communicates with the Acorn board and/or during the first time a new version of CNC12 is started. CNC12 will say "MPU Rebooting". DO NOT power off the Acorn board at this time.. let CNC12 finish the firmware updating process. It is safe to restart the CNC12 software at any point..just don't remove the power from the Acorn board during CNC12 initialization if it is updating the firmware on the Acorn board. If the firmware does get corrupted due to a power removal, this is referred to as "bricked it" (corrupted the firmware). If the Acorn board's blue Heartbeat light is not flashing once per second after boot up then the BBG (the Acorn's motion control CPU) is bricked. The heart beat light indicates that the firmware on the Acorn board is up and running and is ready to connect to CNC12. If no heartbeat exists then the BBG will have to be "De bricked". It is a simple procedure explained here...(note the de bricker instructions can also be used to "build" your own BBG for Acorn use.)

Verify that the PC intended for use with the Acorn CNC Controller meets the minimum performance requirements below. (Note: The Windows PC connected to the Acorn board will be referred to as the “CNCPC”)

We suggest using a Beelink EQI12 Mini PC and a Resistive Touch Screen LCD display with 16:9 aspect ratio (1920x1080 preferred as the CNC12 software is a perfect fit at this size.) You can purchase an Mini CNC PC from Centroid with Windows pre configured for CNC use and Centroid Acorn Free Mill, Router, Plasma and Lathe CNC software preloaded ready to run here.....

But if you want to build, buy or use your own CNCPC here are the Centroid Primary CNCPC requirements:

a.) The multi core PC CPU must have at least a SINGLE CORE minimum benchmark of 1500 (mills, routers, lasers plasma and now required for lathes as well). This is any one core of the multi cores rating. You can look up a single core CPU’s benchmark # using this web site. AVOID all Atom "Mobile" processors or equivalents. Don't mistake the Multi Core Bench mark for the Single Core benchmark of a given CPU. Use the link below for proper single core rating. The new Centroid CNC PC Tuner app will test the PC's performance for you and let you know if the PC is good for CNC control use.

http://cpubenchmark.net/singleThread.html

Resources for cheap PC's that will work as a CNC PC:

https://www.centroidcnc.com/centroid_diy/diy_cnc_gear.html

https://centroidcncforum.com/viewtopic.php?f=60&t=1914

* Be sure to Run the Centroid CNC PC Tuner to configure the PC for CNC use and follow the directions in TB309 for the rest of the steps needed.

b.) An SSD (solid state drive) We only recommend Intel or Samsung SSD’s. Do not use mechanical hard drives.

c.) At minimum, 4 GB of RAM. More is better.

d.) Configure Windows 10/11 for CNC use. Run the Centroid CNC PC Tuner to configure the PC for CNC use and follow the directions in TB309 for the rest of the steps needed.

e.) an Ethernet port (not a USB to Ethernet adapter!), and update to latest hardware manufactures drivers.

f.) A 1920x1080 LCD monitor. 1920x1080 (HD) is preferred, other sizes with a 16:9 aspect ratio will work but screens may be shrunk to fit. Square 4:3 monitors will not work. A touch screen is not required to run Centroid CNC software ( a mouse works just fine) but, a touch screen does work with Centroid CNC software. If you want to use a touch screen the best ones to use in a CNC environment are resistive touch type screen.

A discussion of affordable PC's that meet the requirements on the Centroid Tech Support Forum: http://centroidcncforum.com/viewtopic.php?f=20&t=2794

A copy of the Acorn Installation Manual. found here in the All Acorn Documentation page on the Free Tech Support Forum.

Step 4:

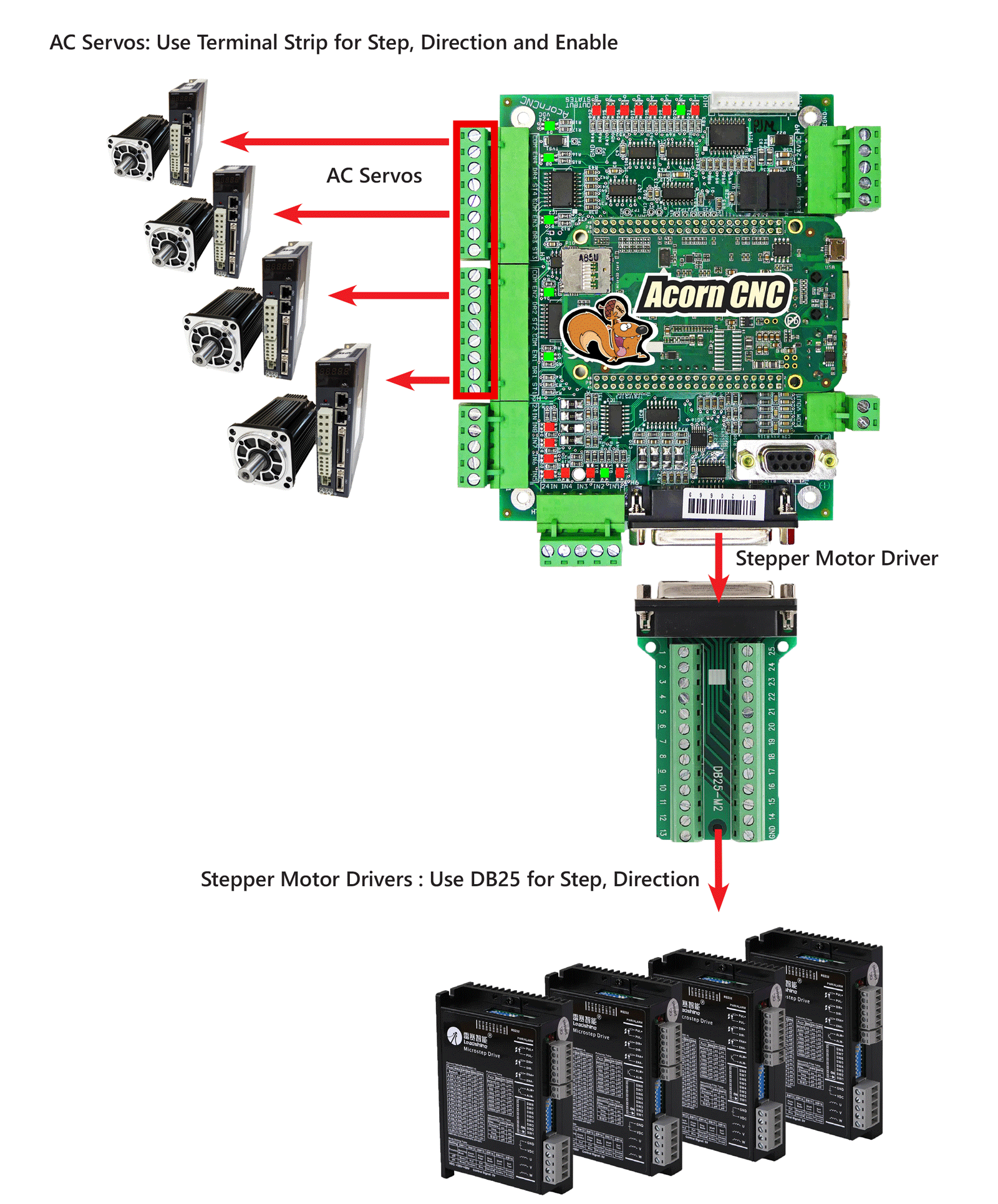

Bench Test Running Motors. Marty shows us how to connect up the Acorn CNC controller to axis motors using the Gecko G540 stepper drive and stepper motors as an example

Bonus: Acorn Input and Output LEDs explained along with Power and Heartbeat and Drive enable LED's

Bonus: How to register for free Centroid CNC Tech Support on the Centroid CNC Community Support Forum

Bonus: Acorn CNC12 software License ordering process explained

Install Manual and Schematics

- Acorn Installation Manual (found on this page that contains all Acorn documentation)

- Acorn hookup schematics (click 'search files' and type in "acorn" on this page)

- Centroid Technical Support YouTube Channel

Sign up for Free Tech Support on the Acorn Forum.

How to register for Free Tech Support.

Acorn CNC Knowledge Base and Tech Tips

and follow these guidelines if you want to post a question.

Tech Bulletins on individual setup subjects.

1.) TB37 Measuring Motor turns per inch.

3.) TB78 Common Wiring Problems

4.) TB294 Configuring Notepad++ for CNC Gcode editor use

5.) TB297 Yaskawa Sigma drive setup for Acorn CNC controller use

Stepper Motor Basics

http://www.geckodrive.com/support-category/step-motor-basics/

Franco CNC Bench Test of Closed Loop Stepper Drive with Acorn.

https://youtu.be/iUCIbDSPn84

and https://youtu.be/U5hnbNnlMTk