DeVlieg CNC Retrofit Horizontal Boring-Jig Mill Control System

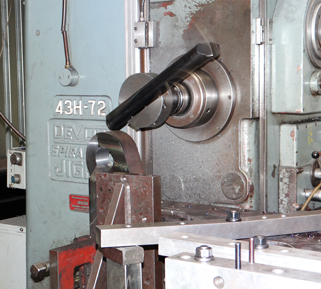

DeVlieg 43H-72 Spiramatic Jig Mill CNC retrofit upgrade.

With worn out Mitsubishi CNC control electronics that were cumbersome and expensive to maintain it was time to bring this classic machine back to life. A new CENTROID M400 CNC control has made this machine profitable again. Utilizing the advantages of the CENTROID MPU11 motion controller along with the GPIO4D controlling Yaskawa servo motors and drives, the new control system is reliable and easy to program.

This DeVlieg 43H-72 is one of two located at this shop in southern California and was retrofitted by William Atkinson, CNC Matters.com.

DeVlieg operator runs G code programs and uses graphical part setup menus and Smart Search.

Smart search allows the operator to stop the job at any point, check his work and then pick up right back where he left off or at any other location within the G code program. Due to the size of the parts this customer works on, it is common to have to setup and relocate the part on the machine many times to complete the job. Centroid fast and easy part setup menus help the operator make accurate setup quickly for a no mistake setup.

DeVlieg 5K-96 Spiramatic Jig Mill CNC Retrofit with Centroid M400 CNC control

It was hard to keep the original control running on this DeVlieg 5K-96 and parts for the original control system on this were getting impossible to find. Time for an upgrade. Increased reliablity and easier operation were the result of a Centroid CNC retrofit by Randy Ellsworth of ViTech Machine, located in Statesville, NC. In additon to the full electronic and electrical retrofit, motor mounts were fabricated ahead of time to facilitate the new AC brushless axis servo motor installation. A new Centroid MPU11 / GPIO4 based M400 CNC control system was installed. This customer builds parts for Gulfstream luxury jets.

Give us a call or fill out our Retrofit Quote request form for more information on DeVlieg Jig Mill CNC Retrofits

DeVlieg CNC Retrofit Video

DeVlieg Retrofit Photo Slide Show