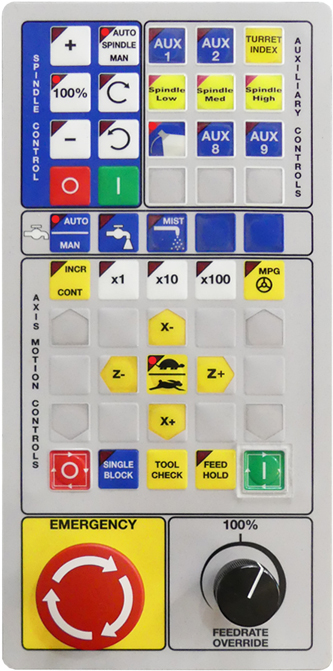

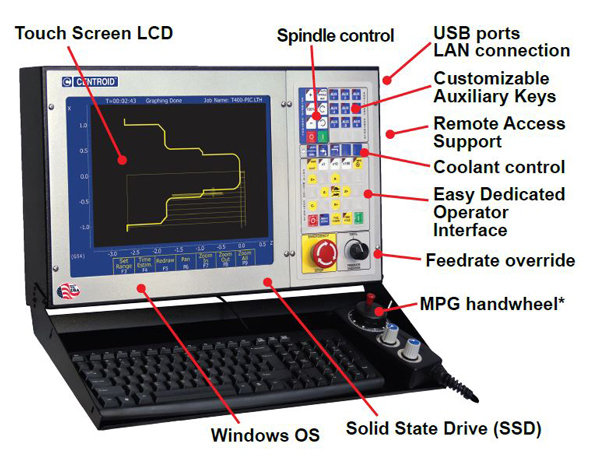

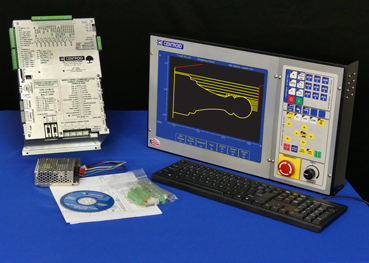

T-400 CNC Control for Lathes, Turning Centers and special applications

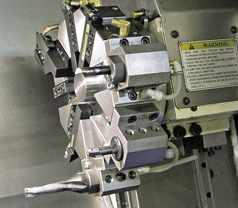

ATC Turret Compatible Electric or Hydraulic

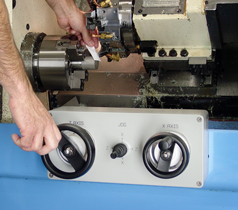

Dual Electronic Handwheels

T400 Brochure click here to download, and here for dimensional drawings

• Long product Life Cycle backed by affordable replacement CNC parts, repair, upgrades and support

• User-Friendly, Rock Solid, Factory Supported, Updateable Centroid CNC software

• Proven, Reliable CNC Software and CNC Hardware designed to work together

• Dedicated, Centroid manufactured Closed Loop CNC Motion Control CPU

Do more with a CENTROID!

• Cut parts the first day with intuitive, straightforward CNC operation

• Increase profit and production with faster setups, easier programming, and reliable operation

• Expand machining capabilities and compete on higher paying jobs with affordable options

• Windows OS: Connect easily to any computer system by using USB, LAN, or Internet Remote access

Comprehensive CNC features:

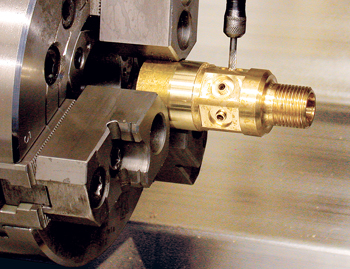

• Compatible with electric or hydraulic tool turrets

• Compatible with hydraulic & air chucks, tailstocks

• Compatible with chip conveyors, bar feeders & parts catchers

• Compatible with dual electronic handwheels

• Tool life & tool wear offset adjustment menu

• "Tool Check": stop, measure, tweak offset & resume

• Front mount, rear mount, gang and live tooling

• Fill-in-the-blank part and tool setup menus

• Runs on industry standard G & M codes

• Built-in G code editor & G code backplot

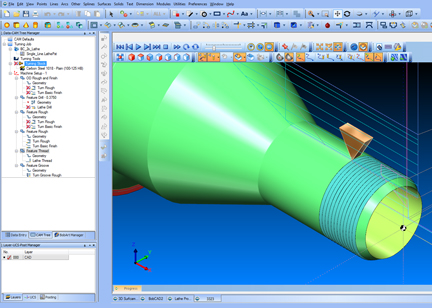

• Compatible with popular CAD/CAM systems

• Dedicated Motion Control DSP CPU

• Reliable, no moving parts Solid State Drive (SSD)

• 15” Touch Screen LCD display

• Run 3rd party software of your choice

• Subprograms, multiple WCS and Macros

• One button push for common machine functions

• Spindle and Axis Load Meter display

• Digital servo drives, AC or DC servo motors

• Laser Ballscrew compensation

• Conversational with Teach mode

• Custom UI Screens for special applications

• Hand Held Electronic Handwheel option

• Remote Access support via internet connection

Run 3rd party software of your choice

• Install and operate most any CAD or CAD/CAM software

directly on the Centroid CNC control

• Allows operator to use a CAD or CAD/CAM program to

look up part dimensions, create and modify part programs

• Utilize CAD/CAM part turning simulation backplot and

verification features directly at the control.

• Open CAD files directly on control via USB or LAN

• Run most any other windows compatible software or

hardware: Skype, Teamviewer, G-code editors, Webcams,

Microphones, Speakers, Wireless devices, backup

Hard Drives, etc.

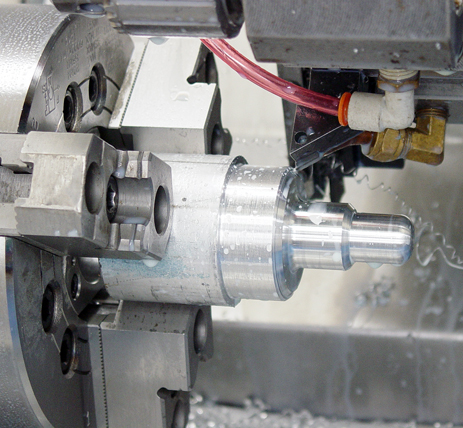

One CNC Control for all your turning needs from Job Shops to Production rooms

The T400 CNC control is suited to a wide variety of turning machine tools from:

- Precision Tool Room Lathes

- Job Shop Flat Bed Lathes

- Production Turning Centers

- Vertical Lathes

- and everything in between.

Customizable to match any CNC machine tool configuration or job requirement.

Retrofit upgrades available for these popular machine tools: Hardinge, Mori Seiki, Fanuc, Anilam, Bridgeport, Prototrak, Ikegai, Bullard, Pratt & Whitney, Mazak, LeBlond, Berthiez, Warner Swasey, Cincinnati, Okuma, Daewoo, Star, Hitachi Seiki and many more.

Heavy Duty CNC console with powdered coated Steel construction is only 2.88" thick and can be easily mounted to a machine tool in a variety of ways. Uses Standard PC keyboard which provide familiar Qwerty layout that are inexpensive widely available replacement options. Dual electronic hand wheels are avail bale as well as the single lathe handheld MPG with axis and increment selector your choice.

Easy file transfer w/ USB & LAN.

Quickly and easily load G code programs and CAD files into the control with a USB thumb drive. Downloading large G-code part programs generated from a CAD/CAM system is now fast and simple. The control automatically recognizes the USB thumb drive and a drive letter shows up on the load menu along with the built-in hard drive. You can even graph the G-code part programs directly from the USB thumb drive to identify the program you want before downloading into the control! USB drive support is a standard feature. Ethernet LAN connection, and MPG connector are also standard features of the M400 CNC control.

Run most any other windows compatible

hardware:Webcams,

Microphones, Speakers, Keyboards, Mice, backup

Hard Drives, Wireless devices etc.

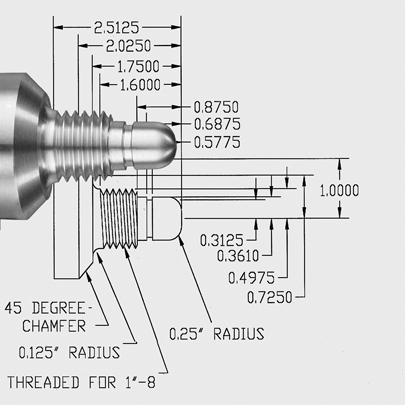

From Print to part in minutes with Centroid's "Intercon" conversational programming for Lathes

• Quickly create part programs right at the control

• Easy “fill-in-the-blank” canned cycles

• Graphical help menu and math assistance for missing dimensions

and Teach mode

• Check your work instantly with tool path graphics

• No knowledge of G-codes necessary

• Smart Threading cycles w/ Thread Data Library

• Intercon automatically generates part G-code

• Seamless integration with cnc control software

• Offline version available for PC use

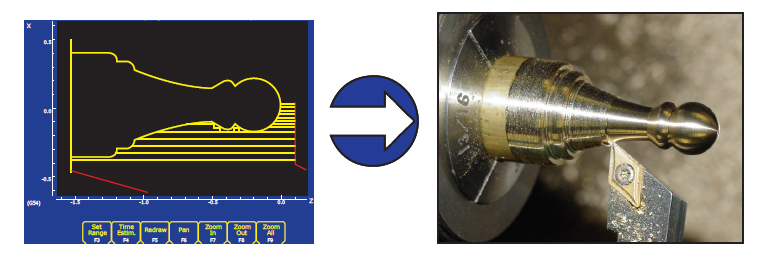

Part Program Tool Path Graphics (aka G-code backplot)

• See a graphical preview of part while programming, graph at any point inside conversational

• See cutter compensated moves

• Preview and step through any part program before running the job

• Easily identify and correct over travel events

• Accurately estimate actual job runtime

• Stop and start the part graphics at any point

• Check G-code for errors before running the job

• Feedrate override knob controls graphing speed

• See feed rate and rapid rate moves

• Zoom in and pan to see detailed areas

Automatic Profiling Cycle, Diameter or End Face

• Automatic profiling generates all the moves necessary to remove material from around the part profile.

• Enter only the finished part dimensions and material around the profile is automatically “roughed off”

Line and Arc Canned Cycles w/ auto Connect Radius and Teach Mode

• Program line moves with ease. Enter what you know: endpoint data, or taper angle and taper length

• Automatic connect radius for lines and arcs and automatic chamfer for lines

• Program Arcs with End Point & Radius, Center Point & Angle, Center Point & Endpoint or Three Points

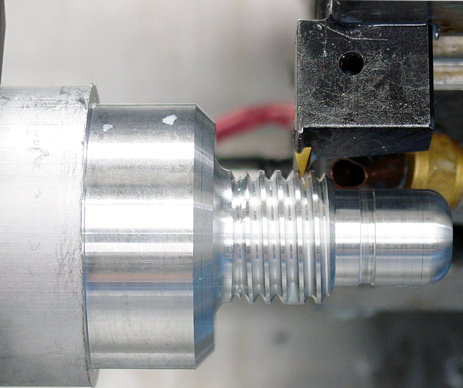

Threading, Grooving, Turning, Cutoff, Chamfering, and Radius Cycles

• Canned threading cycles include: Inside, Outside, Compound, and Tapered (pipe) threading cycles

• Threading cycles can be used by simply selecting the thread from the built-in library or enter your own custom thread using type of thread and entering pitch, diameter, and length

• Designate threads Class with multi pass, spring pass, finish pass controls and multi lead threads

• Grooving: Straight, Chamfered, or Radiused Grooves on the inside, outside, front, or back of the part

• Turning: Diameter or End Face, ID or OD Turning, Straight or Angled, Rough and Finish passes

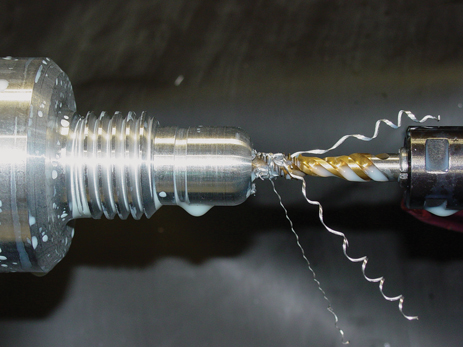

Canned Drill, Bore and Tapping Cycles

• Canned Drill and Bore cycles include:

Peck Drill/Bore, Chip Breaking, Deep Hole Drill/Bore (chip removal), and Drill/Bore

• Use a tap to make threads with the canned Floating-tap or Rigid-tap cycle*

• Specify threads-per-inch, spindle speed, and depth and the control does the rest

Tapering Cycles

• Add any taper to your part, at any angle, by specifying a start and end point, or use the angle and length of the taper

• Intercon will automatically calculate any unknown values

C Axis Positioning

• Used for contour milling and spindle positioning for drilling and tapping.

• Produce special profiles such as square sides, pockets, cams, and even lettering

• Provides accurate positioning around the circumference, on the face, or inside the part

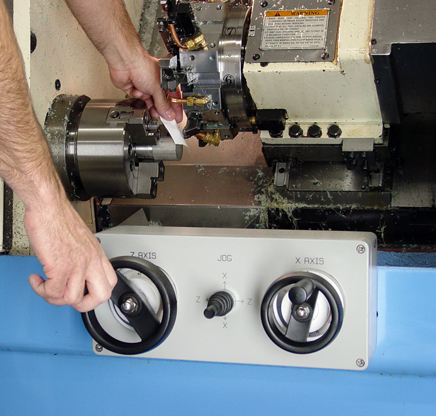

Dual Electronic Handwheels

Intuitive handwheels provide the operator with a fast and easy way to setup a job. Move an axis just like a manual lathe. Great for touching off part zero positions and setting up tool offsets these CENTROID handwheels have a natural feel and can be used in conjunction with the axis Jog buttons on the operators control panel. A center mounted Joy stick allows for easy fast jogging of both the X an Z axis in both directions. The CENTROID dual handwheels can be mounted anywhere on the lathe with the provided sealed mounting box or can be mounted flush into your existing cabinet.

New installations or Retrofit upgrade of existing CNC handwheels

OEM, Pro Install or DIY CNC control systems for new installations or retrofit upgrades

• Pre-engineered CNC control packages are available for: Flat Bed Lathes, Slant Bed Lathes, Turning Centers, Vertical Lathes, Precision Hardinge Style Lathes, Gang Tooling Lathes and many other Turning related machine tools

• Common CNC control configurations are in stock and ready for immediate shipment

• Custom built to any machine tool specifications

• Retrofit upgrade kits for good machines with obsolete controls

• Ready-to-run CNC systems for new machine tools

Ready to run pre-wired closed loop CNC systems with AC or DC Servo motors up to 8 axes, pre configured I/O and pre-wired machine tool accessory cables customized to any machine tool.

DIY CNC Kits

Various Console Mounting Options

CENTROID CNC Service and Support

Remote control from the factory, Team Viewer, and instant messaging.

Centroid CNC controls have a proven reliable track record and offer cool, quiet operation. Our controls are easy to maintain, with autotune, dragplot and self diagnostics. Centroid CNC users are supported by a nation wide network of local Factory Trained Technical Representatives who provide fast affordable service, training and upgrades. Centroid users can stay up with current technology with easy Centroid CNC software updates. In just minutes new CNC features can be added to the control.