CENTROID M400 CNC retrofit control system for milling machines and routers

Now with Windows 10/11, solid state hard drive, and touch screen as standard equipment!

High performance, user-friendly CNC controls for milling applications

M400 Brochure click here to download PDF and click here for dimensional drawings

• Long product Life Cycle backed by affordable replacement CNC parts, repair, upgrades and support

• User-Friendly, Rock Solid, Factory Supported, Updateable Centroid CNC software

• Proven, Reliable CNC Software and CNC Hardware designed to work together

• Dedicated, Centroid manufactured Closed Loop CNC Motion Control CPU

Advanced CNC control features include:

• 4 axis with spindle control standard

• 5,6,7,8 axis simultaneous contouring optional

• DSP high block throughput & high-speed machining

with 2000 line accel/decel lookahead

• Digital servo drives, AC or DC servo motors

• Standard Solid State Drive (SSD)

• Easy-to-use part and tool setup menus

• 15” touch screen LCD display

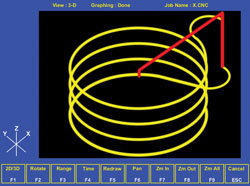

• 3D tool path graphics with runtime display

• Runs on industry standard G & M codes

• Compatible with popular CAD/CAM systems

• Remote Access support via internet connection

• Windows OS, easy networking & file transfers

• Custom UI Screens for special applications

• Run 3rd party software of your choice

• Subprograms, WCS and Macros

• Laser ballscrew mapping

• One button push for common machine tool functions

• Axis pairing, Multiple spindles, Scale inputs

Included Intercon Conversational Programming

• Quickly create part programs right at the control

• Easy “fill in the blank” menus

• Graphical help menu with math assistance for missing dimensions

• Software automatically generates the G-code

• Check work instantly with 3D tool path graphics, graph at any point

• No knowledge of G-codes necessary

• Drilling cycles: Deep hole, Chip breaking, Regular

• Drill BHC, Drill array, Drill repeat

• Lines: end points and polar

• Pockets: rectangular, circular and irregular with auto-cleanout, island avoidance and finish passes

• Repeat whole parts, events, or a matrix of holes

• Mirror and rotate whole parts or one entity

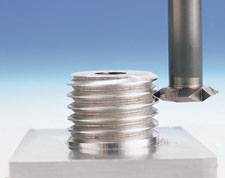

• Threadmilling: inside, outside, left and right handed

• Arcs: EP & R, CP & A, CP & EP and 3-points

• Frames: inside and outside of rectangular, circular

• Teach mode

• Easy 4th axis programming

• 3D Print Additive canned cycles..

Click here for more part programming info.

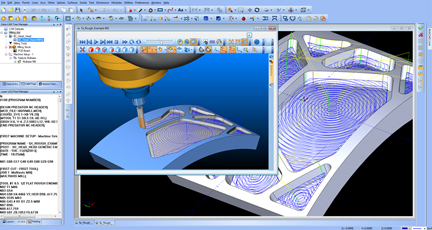

Run 3rd party software of your choice

• Install and operate most any CAD or CAD/CAM software

directly on the Centroid CNC control

• Allows operator to use a CAD or CAD/CAM program to

look up part dimensions, create and modify part programs

• Utilize CAD/CAM part machining simulation backplot and

verification features directly at the control.

• Open CAD files directly on control via USB or LAN

• Run most any other windows compatible software or

hardware: Skype, Teamviewer, G-code editors, Webcams,

Microphones, Speakers, Wireless devices, backup

Hard Drives, etc.

Automatic Tool Changer Control

• Carousel, Swingarm and Rack tool changers

• Control up to 200 tools

• Menu-driven tool changing w/o using G-code

• Random Access, Bidirectional

• Batch ATC Auto tool measure functionality

The CENTROID CNC control can operate a wide variety and types of tool changers. Umbrella type to Swing arm -- the Centroid provides fast repeatable tool changes. Automatic batch measurement is also available when used with our TT-1 Auto Tool Setter. Just highlight the tools you would like to measure and the batch feature will automatically retrieve, measure, and replace each tool automatically.

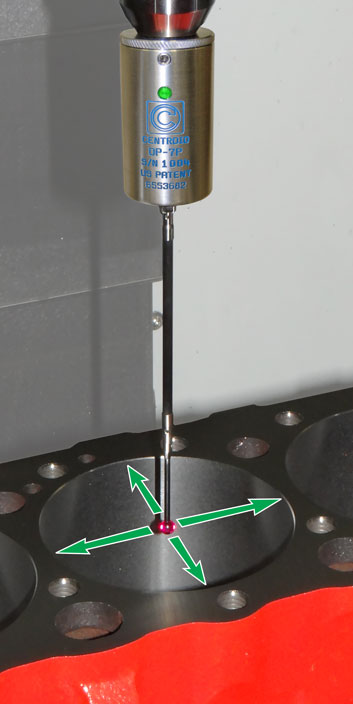

CNC 2D and 3D Digitizing

• Duplicate parts in 2D or 3D

• Easy menu-driven fill-in-the-blank digitizing cycles

• Perform grid, radial, contour & wall following digitizing

• Automatically generates G-code and Cloud Point Data

• Export data to most any CAD/CAM system

for further editing and shape manipulation

• Autonomous cylinder head port & combustion digitizing

• Probe and Software designed to work together

• DP-4 all around .0001" accurate 3D touch probe

• DP-7 specialized long styli application touch probe

Copy and Cut 2D and 3D shapes. Centroid's affordable, effective Digitizing

is the simplest CNC Digitizing on the market. Just record and play

back. Do you have a 2D contour such as a CAM or a 3D part like a mold

or plug? But no print? Let our Digitizing feature copy the part for

you. Digitizing turns your milling machine into a copy machine. Centroid

has overcome the cumbersome problems associated with Digitizing on

other controls. With a Centroid, it's actually one of the simplest

features on the control to use. With our Digitizing feature you will

be able to copy and reproduce an existing shape with little or no

programming! No CAD/CAM necessary, however you can export the Digitizing

information to a CAD/CAM system for further modification. It's very

popular for repairing cylinder head combustion chamber damage, copying

cams, creating molds and plugs from existing objects and many other

uses.

Click here for more on Digitizing...

Automatic Tool Setter

• Effortlessly measure tool heights

• Repeatable results for consistent part production

• Faster and more accurate than manual methods.

• Significantly reduce setup time

• One-touch operation sets tool heights

within 0.0001” in seconds

• Menu-driven automatic tool measurement

• TT-1 conductive, TT-2 non-conductive probes

Setup your tools in a quarter of the time it would normally take! If you often machine short run parts and are always setting up and tearing down for a new job, Auto Tool Set will save you tons of time, while more accurately setting your tool height offsets. With the TT-1 or Tt-2 you can create more parts per hour since the tool set up is so much faster. You'll even save time when you have to replace a dull tool with a new one in the middle of a job. Auto Tool set is completely automatic. Press "measure" and the tool will automatically touch off and set the tool height offset in the tool library.

CNC Probing Cycles

• Touch probe with Probing cycles offers accurate

part and fixture setup with the push of a button

• Automatically set Part Zero position,

quicker and more accurately than manual methods

• Finds edges, corners, bore centers, boss centers and

fixture offsets & angles in seconds

• Automatic Coordinate System Rotation*,

never manually tram a vise again

• Reset fixture locations automatically,

never use a center finder again

• Much faster and more accurate than indicating by hand

• DP-4 Kinematic seat: all around high performance probe

• Specialized DP-7: Solid State design for long styli

• Reliable Plug and Play CNC Probing

• Easy menu driven fill-in-the-blank probing cycles

Dedicated control panel for all common Milling functions

Easy file transfer w/ USB & LAN.

Quickly and easily load G code programs and DXF files into the control with a USB thumb drive. Downloading large G-code part programs generated from a CAD/CAM system is now fast and simple. The control automatically recognizes the USB thumb drive and a drive letter shows up on the load menu along with the built-in hard drive. You can even graph the G-code part programs directly from the USB thumb drive to identify the program you want before downloading into the control! USB drive support is a standard feature. Ethernet LAN connection, and MPG connector are also standard features of the M400 CNC control.

Run most any other windows compatible

hardware: Webcams,

Microphones, Speakers, Keyboards, Mice, backup

Hard Drives, Wireless devices etc.

Rigid Tapping and Threadmilling Perfect, repeatable threads each and every time

• Allows use of solid tool holders with your tap

• Special deep hole tapping cycle for large diameters

and Threadmilling for diameters that are too large to tap

OEM, Pro Install or DIY CNC control systems for new install or retrofits

Ready to run pre-wired closed loop CNC systems with AC or DC

Servo motors up to 8 axes, preconfigured I/O and pre-wired machine

tool accessory cables customized to any machine tool.

• Pre-engineered CNC control packages are available

for: knee mills, bed mills, machining centers,

boring mills, additive 3D printing, routers, and

many other machine tools

• Common CNC control configurations are in stock

and ready for immediate shipment

• Custom built to any machine tool specifications

• Retrofit upgrade kits for good machines with

obsolete controls

• Ready-to-run CNC systems for new machine tools

Not just a box of parts! Centroid's ready to run CNC controls are the fastest and easiest to integrate CNC onto a new machine. The controls arrive ready to install with the control panels pre-configured for your particular machine, saving hours -- if not days -- of installation time. PLC ladder logic is also preprogrammed for your particular machine. The M-400 is available with our affordable DC brush axis motors or AC Brushless servo motors

Designed to last with over 37 years of experience

• CENTROID designs and manufactures its own state-of-the-art CNC control components.

This allows us to provide the industry’s most affordable replacement CNC parts

and CNC support long after the sale.

• Low CENTROID CNC control operating costs increase your bottom line.

• CENTROID is a U.S. owned and operated company with thousands of CNC controls in

operation worldwide.

DIY CNC Kits

Various Console Mounting Options

Plug and Play Centroid CNC rotary tables

True simultaneous 5 axis CNC machining

CENTROID High speed 5-axis machining centers are now available. Bostomatic style with modern day improvements. Fast, Smooth, consistent 5-axis motion. Great for medical, aerospace and any industry needing an affordable accurate made-in-usa 5-axis machining center that is easy to use.

Complete packages available with training. X,Y,Z,A and B motion all at the same time or in any combination. 5 axis control systems are available separately for milling machines and CNC routers for new or retrofit applications.

To see a video of our 5 axis machining center in action...click here...

CENTROID CNC Service and Support

CENTROID CNC controls have a proven reliable track record and offer cool, quiet operation. Our controls are easy to maintain, with autotune, dragplot, self diagnostics and remote access support. Centroid CNC users are supported by a world-wide network of local Factory-Trained Technical Representatives who provide fast affordable service, training and upgrades. Centroid users can stay up with current technology with easy Centroid CNC software updates. In just minutes new CNC features or accessories can be added to the control.